Determination of Contact Angle Values of Heat-Treated Spruce (Picea abies) Wood with Image Analysis Program

Introduction

One of the most important problems of wood materials is the dimensional change and decay with environmental impact [1- 4]. Chemical methods used in the wood material modification, are easily applied, and the wood protects against deterioration and decay of material [5]. Heat treatment; it is an alternative modification method to the use of chemicals in order to increase the dimensional stabilization of the wood material and to protect it against tree pests [6]. The aim of this study is to determine the surface contact angle values of heat treated (HT) and unheat treated (UHT) spruce wood and to evaluate about the dynamic wetting properties of this material.

Material and Methods

In this study were studied on spruce (Picea abies) wood. The timber (heat treated and unheat treated) used in the study was obtained from the forest products factory. Firstly, contact angles were determined by using contact angle method to determine surface wettability properties on spruce wood materials. For this purpose, 30 pieces samples have been cut (spruce; 15 heat treated materials, 15 unheat treated materials) in 20x20x30 mm dimensions. The samples were stored until they reached equilibrium humidity in air conditioning cabinet [7-10]. After the water drop (5 μl) was dropped onto the surface, images were taken every 5 seconds during 30 seconds. The images were transferred to the image analysis program ‘‘image j’’ and the contact angle values of the drops were determined by this program.

Results and Discussion

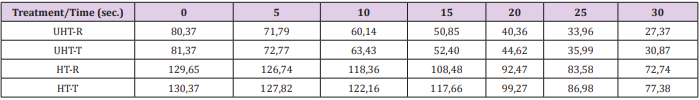

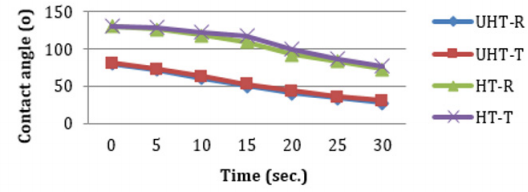

The tangential (T) and radial (R) direction contact angle values of the spruce (heat treated-unheat treated) test samples are given in Table 1 and Figure 1. At the end of the 30th seconds (lowest) contact angle of the heat-treated spruce samples is 77.38° in the tangential direction and 72.74° in the radial direction. At the end of the 30th seconds (lowest) contact angle of the unheat treated spruce samples is 30,87° in the tangential direction and 27,37° in the radial direction. Kocaefe et al. (2008) determined that the surface contact angle of the wood material increases with the heat treatment application.

Table 1: Results of contact angle values on spruce wood surface.

Note:

*UHT: Unheat-treated HT: Heat-treated R: Radial section, T: Tangential section

Conclusion

It was determined that the wettability properties of spruce wood decreased by the application of heat treatment. In line with this result, the use of ThermoWood treated wood materials outdoors in damp environments will be more favorable compared to untreated wood material. “Image J” program could use to determine the dynamic wetting properties of the wood surface.

For more Articles on : https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.