Effect of Operating Parameters and Particle Size of Calcium Carbonate on the Physical Properties of Latex Paint

Introduction

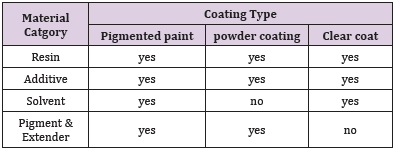

Paint is a liquid which spreads over a substrate in the form of thin layer and it is transformed into a solid adherent film [1]. There are two major functions of paint. One protection and other is decoration. The earliest known use of paints dates back more than 30,000 years to cave paintings in Spain [2]. These paints were simply mixtures of colored earth, soot, grease, and other natural substances. The ancient Greeks, Romans, and Egyptians used natural resins and raw materials to decorate and identify statues, tools, vessels, and buildings [2,3]. These natural ingredients include vegetable gums, starches, and amber. In China and India, shellac resins and beeswax were used over 2000 years ago as a decorative coating which also doubled as a protective function [4]. The earliest paint formulation dates back roughly 900 years to a German goldsmith and monk, Rodgerus von Helmershausen [2,3]. His formulation described the manufacturing of paint by mixing linseed oil and amber, referred to as paint boiling, which was further refined and developed into the Industrial Revolution [2,3]. Synthetic polymer chemistry also developed at this time with Carothers and others in the 1920s [5]. Paint is used to protect and color the substrate. Components of paint are solvent, pigment, filler, additives and binder. A coating is a product based on organic binders, which provides a cohesive, non-absorbent, protective film [2]. Differences in the composition of the various coatings systems are presented in (Tables 1 & 2).

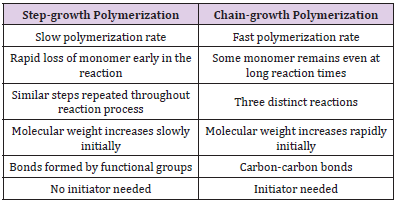

Common to all three coating systems are the resin and additive. Clear coats are optically inactive; therefore pigments and fillers are not present. Powder coatings are not in a liquid medium; therefore a solvent is not present. Paints are liquid materials that are optically opaque coatings that form when applied by brushing, rolling or spraying [2,3]. The technical definition of a binder is the non-volatile part of a paint excluding the pigments and filler, which includes the non-volatile additives [2]. Binder forms the film of the paint. Binder is a polymer which has impact on important properties of the paint like adhesion to the substrate, sheen, application properties, color acceptance, durability and flexibility. There are different types of binders like synthetic binders and natural binders. Water based paints binders include poly vinyl acetates, poly vinyl acrylic, styrene acrylic, pure acrylics, etc. Oil-based paints include alkyd resins, polyurethane resins, melamine resins, etc. Natural oils or fatty oils were important film forming agents which were able to convert a low viscosity liquid into a solid [3]. Synthetic resins came about in the 1920s with the advancements in polymer chemistry. The primary benefits of synthetic resins are that products can be tailored with specific properties with nearly unlimited availability. The different resin systems are mentioned above, all of which are either step-growth or chain-growth polymerization [6].

Chain-growth reactions typically have three reactions – initiation,

propagation, and termination. Step-growth polymerizations are

reactions between functional or multifunctional monomers without

an initiation or termination step. Characteristics common in

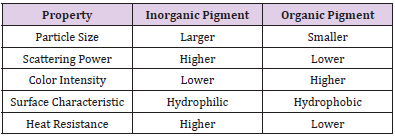

pigments include extreme optical characteristics, particles smaller

than 10 μm, being insoluble in water and most organic solvents,

and being chemically inert or chemically stable [7]. A comparison

between the organic and inorganic pigments is presented in (Table 3)

[2]. Colored inorganic pigments are typically variants of iron oxides

[3]. Pigments are used for giving color contribution in paints. There

are different types of pigments like natural or synthetic. Pigments

give opacity to the paint film. There are many kinds of pigments like

titanium dioxide, phthalocynine blue, pthalocyninered, iron oxide,

etc. Common filler materials include carbonates, silicon dioxide,

silicic acids, silicates, and sulfates [2,3,6]. Fillers are used to give

toughness and lower the cost of the paint by increasing the density

of the paint. The examples of natural fillers are grounded calcium

carbonate, magnesium silicate, etc. The examples of synthetic fillers

are precipitated calcium carbonate, aluminum silicate, etc. These

pigments and extenders are commercially available in solid or

slurry form. Slurry is an aqueous solution that contains dispersed

pigments or extenders. In a paint application, the pigment and

extenders are eventually dispersed in some sort of medium.

The dispersion process involves 3 steps – wetting, separation,

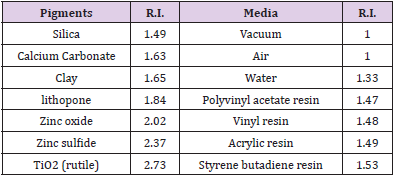

and stabilization [6]. The refractive index can be described as the

degree of bending of light as it passes through a material. This

value is a dimensionless value and is typically referenced to light

traveling in a vacuum. Larger refractive indexes reflect a greater

degree of bending of light. The refractive index of pigments and film

formers are presented in (Table 4). TiO2 is not used as a biocide,

but has some antimicrobial properties due to the photo catalytic

reaction mentioned earlier [8,9]. Filler or extender particles such

as calcium carbonate (CaCO3) primary serve as replacement for the

binder material. Reasons include the lower cost of filler materials

or formulation above critical pigment volume concentration.

Pigment volume concentration (PVC) is the most widely accepted

quantitative description of paint film composition [1]. PVC is

expressed as volume percentage of the pigments and fillers to

that of the volume of the dry film expressed as a whole number.

Volume is used rather than weight because pigments scatter based

on volume. PVC values are quantifiable between 0 – 100. Solvent is

used to form a homogenized mixture by dissolving the polymer and

pigments. Solvent also adjusts the viscosity of the paint. Solvent is

a volatile part of the paint. Functions of solvent also include flow

control flow, stability of paint liquid and improving application

properties.

The main solvent for water based paints is water. The solvent for oil-based paints can be white spirit, mineral turpentine oil, alcohols, ketones, etc. Additives are liquids which gives dramatic effect on paint quality. There are different functions of different additives. Some additives change the surface tension of the paint film; some additives enhance the flow pattern of the paint or improve the appearance of the paint. Different additives have different impact on the liquid paint or paint film like changing wet edge, increasing stability of the pigments used, ant freezing effect, low foaming, less skinning, etc. There are different types of paint additives like gelling agents, hydroxyethyl cellulose, emulsifiers, different biocides, UV stabilizers, etc. Emulsion paints are waterbased paints containing water, binder, additives and pigments. Curing of Emulsion latex paints is done by coalescence. Coalescence is a process in which the coalescing solvent draws together and the binder particles are soften to bind them together into irreversibly bound networked structures. Alkyd enamel are paints that cure by oxidative crosslinking. These paints need drier additives like cobalt naphthenate, calcium naphthenate and lead naphthenate to start oxidation process for drying. Some paints are one or two package coatings. These paints dry through a chemical reaction.

Materials and Methods

The following Instruments and Analyzers Were used to Analyze Various Properties of Paint Samples

1. Conventional Agitator, (laboratory mixer manufactured by

BEVS Industrial Co. Ltd., China. Model: BEVS 2501/1)

2. Brookfield DV2T viscometer

3. Nano grinding machine (nano mill manufactured by Dongguan

Longley Machinery Co. Ltd. China. Model no. NT-1L)

4. Spectrophotometer, model data color 110

5. Grind Gauge, sheen UK, range 0-100 μm

6. Hiding Power Charts, sheen UK, Coated, 255 x 140 mm

7. Automatic film applicator (manufactured by BEVS Industrial

Co. Ltd., China. Model Number :BEVS1811/2)

8. Tri-Glossmaster , sheen UK, angles 20-60-85°

9. Wet abrasion scrub tester

10. Stop watch

11. Cryptometer , sheen UK, with K007 plates

12. Pyknometer, sheen UK

13. Malvern Mastersizer, Malvern Instruments Ltd. UK.

14. Brookfield KU-1+ viscometer

15. High speed agitator, rpm 1400

The Following Chemicals were used in the Preparation of Paint Samples

1. Water

2. Dispersant, solution of an ammonium salt of an acrylic polymer

in water

3. Calcium carbonate, 400 mesh particle size

4. Hydroxyethyl cellulose thickener powder

5. Ammonium hydroxide solution (25% actives)

6. Latex binder, which is ter polymer of vinyl acrylic emulsion

7. Biocide A, a water based combination of chloromethyl-/

methylisothiazolone (CMI/ MI) and O-formal

8. Biocide B, a combination of two isothiazalone derivatives that

can provide broad-spectrum micro-organism control in waterbased

coatings

Sample Preparation

Determination of Dispersant Demand

The first step in sample preparation was to determine dispersant demand for current 400 mesh calcium carbonate sample. The complete covering of the surface is an indispensable prerequisite to achieve an ideal stabilization of the dispersed pigments. The fact that the viscosity of pigment slurry reaches a minimum when the pigment surface is completely covered with a dispersant is used to determine the dispersant demand. The dispersant is added in portions to the stirred pigment slurry. After the addition and mixing the viscosity is measured at low shear rates (e.g. with a Brookfield viscometer). The dispersant is added until a minimum of viscosity or constant viscosity is obtained in the viscosity measurements [10].

Procedure for Dispersant Determination

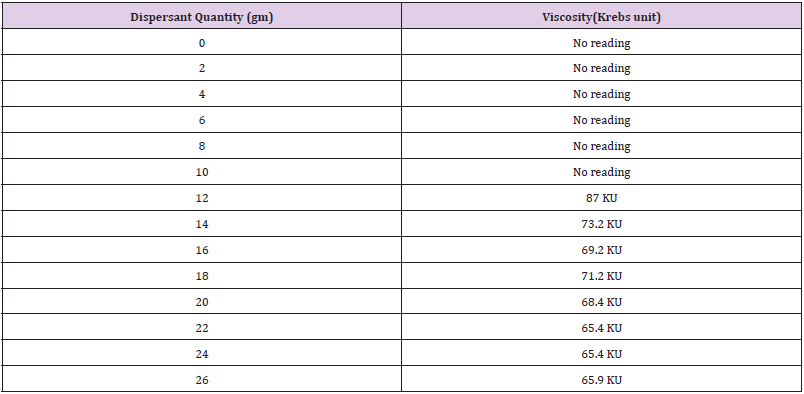

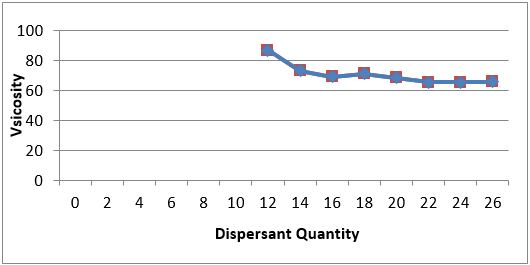

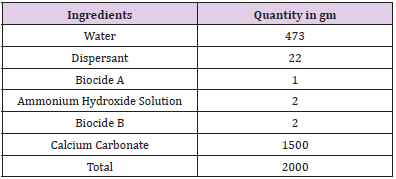

440 gm water was taken in 2500 mL agitated tank of laboratory mixer (Figure 1). Mixing at 500 rpm was started and 1500 gm calcium carbonate of particle size 400 mesh was added in mixing tank. Dispersion of calcium carbonate slurry was done for 05 minutes under 1000 rpm. Viscosity was measured at 25C using Brookfield KU-1+ viscometer following the standard ASTM D562. i.e. “Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer”. The effect of successive addition of 2 gm dispersant on the viscosity of the sample was observed under the same operating conditions as shown in the (Table 5). The procedure was continued till no significant change in viscosity was observed. (Figure 2) shows that optimum dispersant demand was 22 gm for 1500 gm CaCO3 of particle size 400 mesh after which no significant change in viscosity was observed.

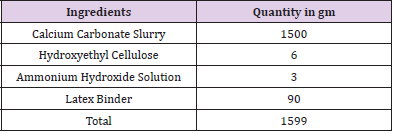

Calcium Carbonate Slurries Preparation

The composition of calcium carbonate slurry was prepared as shown in (Table 6) using nano mill (Figure 3) adjusting pneumatic pump pressure between 0.2 to 0.4 MPa. The speed of the nano shaft was adjusted at 2500rpm.Flow rate of calcium carbonate slurry coming out of the nano mill was adjusted around 3 gm/ sec. Dispersion was checked through ASTM-D 1210. i.e. “Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage”. The term ‘fineness of grind’ is defined as the reading obtained on a gauge under specified conditions of test and the reading indicates the depth of the gauge at which discrete solid particles are readily discernible. Dispersion of calcium carbonate slurry found on hegman guage was below 10 micron. The similar composition (Table 6) was prepared using laboratory mixer. Dispersion of calcium carbonate slurry found on hegman guage was 50 micron.

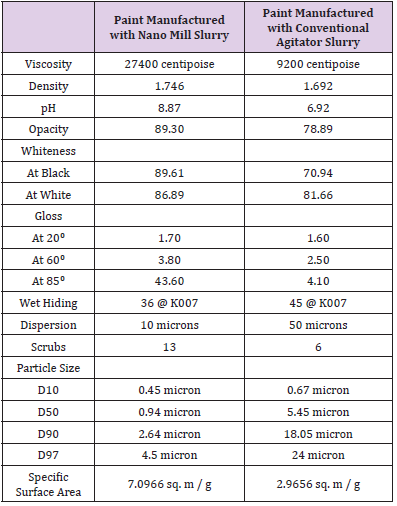

Determination of Various Properties of Paint Samples

Panels Applications

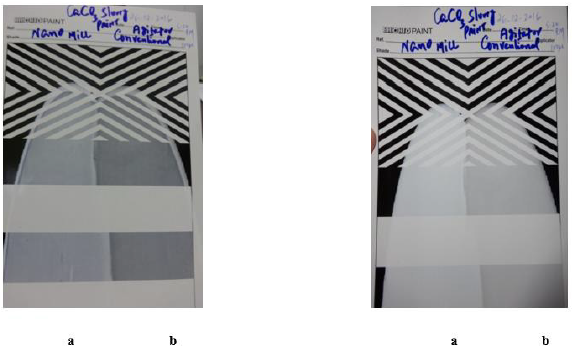

Panels are applied on hiding power charts through Automatic Film Applicator following the standard ASTM D 823-95.i.e. “Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels” as shown in (Figure 4). This standard is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of Subcommittee D01.23 on Physical Properties of Applied Paint Films. From the panels drawn, difference in physical properties of latex paints were observed in terms of viscosity, density, pH values, wet hiding, gloss, smoothness, drying time, whiteness, scrubs and opacity. The results so obtained are summarized in (Tables 7 & 8).

Figure 4: Comparison of Wet panel (left) and Dried panel (right) for

(a) nano mill

(b) and conventional agitator.

Wet and Dry Opacity

Wet hiding was checked through Crypto meter. The Crypto meters offer a quick method to determine the wet opacity, hiding power and coverage in square meters per liter of liquid coating materials. A small sample of liquid coating (approximately 4ml) was applied on the joint line of the black and white base plate, the top plate (pins facing downwards) was placed across base plate joint line the sample forms a wedge of paint, (maximum thickness nearest the pins) by sliding the plate back and forth till the sample perfectly hides both the black and the white section of the base plate. At the position of hiding a reading was observed on the engraved scale of the Base Plate, this was then converted into covering power (Square meters/liter).Top Plates (number K007) were offered with each of the Crypto meter products to cover a range of film thickness.

Gloss Measurements

Gloss was tested through Tri-Gloss master following the standard ASTM D2457. i.e. “Standard Test Method for Specular Gloss of Plastic Films and Solid Plastics”.

Dry Hiding and Whiteness

Dry Opacity was checked through Spectrophotometer data color 110.

Drying Time

Drying time was measured through stop watch at ambient temperature.

Adhesion / Scrubs

Scrubs were checked through Wet abrasion scrub tester following the standard ASTM D 3450. i.e. “Standard Test Method for Wash ability Properties of Interior Architectural Coatings”.

Viscosity

Viscosity was tested through Brookfield DV2T latest viscometer following the standard ASTM D1084. i.e. “Standard Test Methods for Viscosity of Adhesives”.

Density

Densities of the samples were measured through Pyknometer following the standard ASTM D1475. i.e. “Standard Test Method for Density of Liquid Coatings, Inks, and Related Products”.

Specific Surface Area and Particle Size

Specific surface area and Particle size of calcium carbonate slurries manufactured through nano mill as well as through conventional agitator was tested with Malvern Mastersizer

PH Value

PH values of the samples were tested through pH meter following the standard ASTM ASTM E70 - 07(2015). i.e. “Standard Test Method for pH of Aqueous Solutions with the Glass Electrode”.

Discussion and Results

Paint in which calcium carbonate slurry processed from Nano mill showed brilliant results in terms of wet opacity, dry opacity, gloss, smoothness and drying time compared to the paint in which calcium carbonate slurry processed through laboratory mixer as shown in (Figure 4). All quality parameters were significantly increased in the paint in which calcium carbonate slurry processed from Nano mill.

Conclusion

It is observed that with the reduction of particle size of calcium carbonate, latex paint showed better results in terms of better hiding, better whiteness, higher gloss, more adhesion. Calcium carbonate slurry processed through Nano mill showed exceptionally good compared to conventional agitator. The slurry processed through Nano Mill reduced the particle size of calcium carbonate from 37.5 microns to 2.63 microns while the slurry processed through conventional agitator reduced the particle size of calcium carbonate from 37.5 microns to 18.05 microns. Furthermore, the paint manufactured with Nano mill slurry showed better Whiteness, wet hiding, dry hiding, adhesion and gloss than the paint manufactured with conventional agitator.

For more

Articles on : https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.