Cds and Cdse Quantum Dot Solar Cells Production and Improving Efficiency of the Cells by Ion-Doped Quantum Points Cds Holmium

Abstract

This project aims to improve the efficiency of solar cells doped by CdS quantum dot and Ho+3

ion. Successive Ionic Layer Absorption and Reaction (SILAR) and

Chemical Bath Deposition method (CBD), were used to deposit a CdS/CdSe

layer on TiO2 film. According to J-V diagram, it is concluded that adding holmium ions (Ho3+) will enhance the efficiency of quantum dot sensitized solar cells up to 2.53%.

Keywords: Solar Cells; Quantum Dots; Holmium

Abbrevations: QD: Quantum Dots; SILAR:

Successive Ionic Layer Absorption and Reaction; CBD: Chemical Bath

Deposition Method; MEG: Multiple Excitation Generation; EIS:

Electrochemical Impedance Spectroscopy; XRD: X-ray Diffraction; FTO:

Fluorine Doped Tin Oxide

Introduction

Nowadays, energy issues have been challenged as the most important

human necessities. In the meantime solar or photovoltaic cells have been

attended in order to transferring of solar energy to electricity in

which solar energy has been used as a clean, unexpansive and available

energy source [1-3]. Solar cells are divided into different types such

as dye sensitized, silicone solar cells, molecular, GaAs and quantum

dots (QD) [4, 5]. Recently, QD solar cells have attracted great

attention because of their low cost, high surface area and more quantum

yield [6-8]. In QDs, Multiple excitation generation properties (MEG)

cause a few electron transfers from valance band to conductive band by

incident of just one photon which increases absorption in solar cell and

finely leads to high performance of solar cell [9]. Some QDs are used

in preparation of solar cells such as: InAs, CdTe, PbS, InPO4,

CdS, CdSe, etc. Using CdS and CdSe simultaneously has a good effect on

emission of light because of increasing of band gap via a synergic

effect [10-12]. There are some methods for deposition of QDs onto TiO2 like chemical bath deposition (CBD), SILAR and hot injection growth method. In cathode electrode, Pt or Cu2S is used which because of high cost of Pt using the Cu2S is more popular and common [13,14]. In order to increase electron injection from QD to TiO2, coating a layer of ZnS has a great effect via omitting surface-nods made on TiO2 that this layer improves quality and efficiency of solar cells. In many inves

tigations, I-/I3- solution is used as electrolyte. However,

because of corrosion of solar cells by this redox complex solution,

polysulfide solution S2-/Sx2- is used as a substitute electrolyte.

A new method for improving the solar cell performance is introducing

some metals such as Mn, Ni, Ag, Cd etc to cells [15-18]. In this work

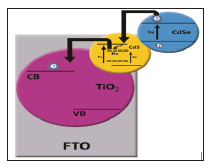

existence of Ho3+ ion in QDSCS cells was used for the first time in order to improvement in photovoltaic performance of QDSCS (Figure 1).

Figure 1: Schematic of the FTO TiO2/CdS: Ho/CdSe

electronic structure. Direct arrows indicate the electron hole

photogeneration. Dashed arrow indicates the electron transfer from CdS

CB to the midgap electronic states and direct curved arrows are related

to electron transfer from CdSe to CdS QDs and from CdS trap states to

TiO2 CB.

Figure 1: Schematic of the FTO TiO2/CdS: Ho/CdSe

electronic structure. Direct arrows indicate the electron hole

photogeneration. Dashed arrow indicates the electron transfer from CdS

CB to the midgap electronic states and direct curved arrows are related

to electron transfer from CdSe to CdS QDs and from CdS trap states to

TiO2 CB.

Experimental Section

Apparatus: SEM-EDX model Irost was applied for. Solar simulator

model SIM800. Bath-Ultrasonic model (Sonica). Water purification

system model No. F3JN94307E. Electrochemical Impedance

Spectroscopy (EIS) was performed on IM6ex Electrochemical

Workstation (ZAHNER) over a frequency range of (1×105–1×10−1)

Hz with 10 mV ac amplitude under forward bias of (-0.6) V in

the dark. Formation of cells by ion-doped quantum points CdS

holmium were analyzed by means of a Philips X-ray diffraction

(XRD) equipfped. The XRD data were collected in the scale of 2Ɵ =

10–80˚ a scanning speed of 3˚ min-1.

Materials: Cadmium nitrate tetrahydrate (Cd(NO3)2.4H2O, Alfa

Aesar, 98.5%), Sodium sulfide nonahydrate (Na2S.9H2O, aladdin,

≥98.0%), Nitriloacetic acid (N(CH2COO)3, sigmaaldrich, ≥99.0%),

Copper(II) sulfate pentahydrate (CuSO4.5H2O, sigmaaldrich,

99.99%), Holmium (III) hexahydrate (HoCl3.6H2O, sigmaaldrich,

99.9%), Sodium hydroxide (NaOH, Merck, 99.0%), Sodium sulphite

(Na2SO3, sigmaaldrich, ≥98.0%), Zinc acetate (Zn (CH3COO)2.2H2O,

Merck, 99.5%), Selenium powder (Se, Acros, 99.5%), Copper (II)

nitrate (Cu(NO3)2.3H2O) and Sulphur powder (S, VWR Chemicals,

99.5%), Fluorine doped tin oxide (FTO) glass, TiO2 nanoparticle. All

reagents and solvents were purchased from commercial sources

and were used without further purification.

Preparation of CdS/CdSe/Ho3+ Solar Cells: First, we deposited

a thin film of TiO2 on FTO transparent conductive layer According

to doctor blade method. Secondly, the electrode was heated up to

125 °C for 6 minutes and then cool down to 25 °C. This process

was repeated until a desired thickness was achieved. To prepare

X electrode, TiO2 photoanodes were placed in a 10mL of cadmium

nitrate solution (1.17g in water) for 5 minutes and then were washed

with distilled water. Then, TiO2 photoanodes were immersed in a

10mL solution containing 2.14g sodium sulfide for 5 minutes. This

cycle was repeated for three times. The resulting electrode was

used as the control electrode. To prepare Y photoanode, plunge

a photoanode was immersed in a 10mL of solution with 1.17g of

dissolved cadmium nitrate and 0.284g Ho3+ for 5 minutes, and

then the sample was dried. The sample is added to the solution of

2.4g of Na2S per 10mL H2O. This cycle was repeated for 3 times.

The electrodes were dried at room temperature. Based on reported

synthesis by Samadpour et al. [19]. In order to prepare CdSe, 1.26g

of sodium sulfite and 0.315g of selenium powder was refluxed

in 50mL of distilled water under nitrogen gas for 5 hours at a

temperature of 80-85 °C at 400-500rpm.

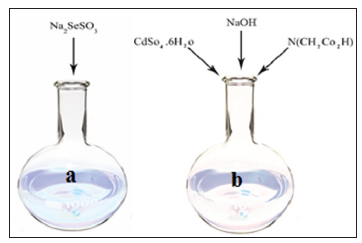

The result is the formation of sodium selenosulphate (Solution of

a). According to Figure 2, different solutions with different volumes

were prepared. 1.2g of cadmium sulphate were dissolved in 50mL of

distilled water. Separately, 1.40g of sodium hydroxide was dissolved

in 10mm of distilled water. Moreover, 1.65g nitriloacetic acid was

dissolved in 40mL of distilled water in a round-bottom flask and

then three samples were mixed and finally added to the b solution

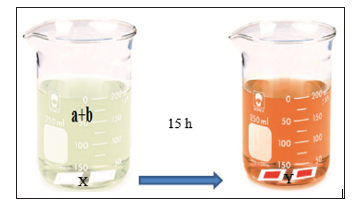

(Figure 2). The final products of a and b was placed in a beaker of

200mL. The synthesized electrodes were kept away from sunlight

for 15 to 18 hours at 2 to 3 °C, Ultimatelly, the electrodes were

washed with distilled water (Figure 3). The electrode immersed in

a solution consist of 0.219g of zinc acetate, 10mL of distilled water

and 0.24g sodium sulfide Na2S. This cycle was repeated three times.

FTO glass was immersed in an aqueous solution of 1.2g copper

nitrate in 10mL of distilled water for 30 seconds and then was

washed with ethanol. This cycle was repeated for 5 times. Finally a

black thin layer of CuS appeared on FTO. Three aqueous solutions

containing 1.2g Na2S, 0.16g S, 0.2g NaOH were prepared separately

and 5mL of each solution was mixed in a round-bottom flask for 90

minutes at the room temperature.

Figure 2: Preparation of a solution (sodium sulfite+

selenium powder) and b solution (cadmium sulphate+

sodium hydroxide+ nitriloacetic acid).

Results and Discussion

SEM

To determine the particle sizes in anodic sub-layer coated by a

layer of TiO2 (20-40nm) and to measure the thikness of the layer’s

SEM-EDX analysis was performed. (Figure 4a) shows SEM image

of TiO2 layers (20 to 400nm) that indicates a porous surface and

uniform particle size. The diameters of first and second layers are

estimated to be 3.77μm (TiO2-400nm) and 4.72μm (TiO2-200 nm)

respectively. SEM images in Figure 4b shows that surface morphology

has been changed in the presence of CdS/CdSe quantum dotes

and shiny dots with 500nm size is appeared that can be related to

CdS/CdSe quantum dotes. The diameter of first and second layers

have changed to 4.03μm and 4.27μm, respectively. Finally, the

thicknesses of TiO2 layers are shown to be 4.04μm and 6.32μm for

first and second layers in Figure 4c, respectively.

Electrochemical Impedance Spectroscopy (EIS)

Figure 7 shows the electrochemical impedance spectra (EIS) of

the CdS/CdSe and CdS/CdSe/Ho. Nyquist curves obtained from EIS

measurements were fitted with equivalent circuit model as shown

in Figure 7. Recombination resistance (Rre) of CdS/CdSe and CdS/

CdSe/Ho samples are 263.30Ω and 628.23Ω, respectively, which

means the electrons and holes recombination in the Ho-doped

CdS/CdSe solar cells are less than that of CdS devices. Thus, the less

charge recombination can be observed in CdS/CdSe/Ho.

Conclusion

Doping of few amounts of Ho3+ ions improves electronic and

photo-physical properties of quantum dots and creates an electronic

level at the middle gap area. This electronic state changes charge

separation and reduces electron-hole recombination. Changing in

the type and amount of impurity causes different electronic and

photonic properties of nanocrystal semiconductors. In this work,

quantum dot solar cells were fabricated, and some investigations

were performed on their structure and it was indicated that quantum

yield increased from 0.87% to 2.53% by adding Ho3+ metal

ion. Using Ho3+ for surface modification leads to increase in yield

of solar cells which it can be concluded that adding lanthanides

ions increase the performance of quantum dots because of electron

transportation properties and these cases may increase quantum

yield of nanoparticle solar cells.

The Drive to Succeed: The Instructional Leader - https://biomedres01.blogspot.com/2020/03/the-drive-to-succeed-instructional.html

More BJSTR Articles : https://biomedres01.blogspot.com

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.