Assessments of Gaseous and Particulate Matter Emissions from Biomass Combustion and their Effect on Human Health

Introduction

Currently, our existence on the Earth planet is being highly threatened because of many apocalypse scenarios in relation with environmental pollution phenomenon. These various pollutions are caused by both anthropogenic and industrial activities. Indeed, the gaseous and the particulate emissions which are harmful for the fauna and the flora are in continuous increase up to a critical point at which we computed more than 10000 organic PMs in an urban atmosphere [1,2]. Nevertheless, it exists always a dispatching concern over the planet warm and the aerosols which are suspensions of solid and liquid particles in air. Indeed, the most crucial factor that governs the climate change over the twenty-first century is the Equilibrium climate sensitivity (ECS) caused mainly by the greenhouse gases; CO2sub>, H2O, CH4sub>, N2O etc. It is defined based on the increase in the planet mean surface temperature resulting from doubling of CO2 concentration in the atmosphere when it is coupled to a slab ocean model [3]. It is to be mentioned that this factor (ECS) of every climate model ever developed has given always positive value. This is a strong indication of warmer equilibrium climate when the CO2 content is in a continuous increase in the atmosphere and everybody knows that it is currently the case. In addition all tested models in the project of the 4th Assessment report of the Intergovernmental Panel on Climate Change (IPCC) show an ECS in the range of 2-4.5°C [4].

Researchers’ interests to aerosols are relatively recent by comparison to greenhouse emissions. However, the aerosols particles can also play an important role on the global climate change [5-6]. Indeed, they can either intensify or moderate the greenhouse gases effects via the scattering or the absorption of both external solar radiation and thermal Earth’s surface emitted radiation. Phenomenon of scattering and absorption of light by aerosols depend strongly on the aerosols size distribution, their chemical composition and the wave length of the incident radiation [7]. It is to be highlighted that the scattering is predominately a function of particle size, morphology and chemical composition, and it concern mainly PMs in the range of 0.1-1μm. However, the absorption by aerosols is related to the whole spectrum and is due to near-graphitic carbon (known under elemental or black carbon) produced via combustion process [7]. In addition, the aerosols under the cloud condensation nuclei are able to modify substantially the radiative properties of the atmosphere. Moreover, despite the low aerosol’s concentrations 10-10 to 10-14 (which is the volumetric ratio of aerosol particles to atmospheric gases) their effect on the atmosphere change is significant [8]. However, aerosols particles don’t contribute only on violent climate change, but also affects human health seriously.

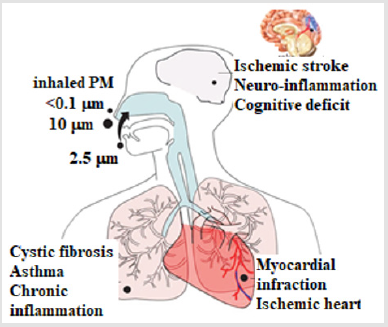

Indeed, air we continuously inhaling is enriched with particulate matter pollutants from many different sources. These PMs are of many types depending on the geographical distribution, area, anthropogenic and industrial activity, and season. Workers in industrial field are more exposed to air pollution. It is proven that aerosols produce serious effects on different parts of our body; the skin, the arteries, the lungs, the heart and the eyes as it is illustrated below (Figure 1) [9-15]. Also, the brain can be affected by aerosols depending on the particle size and charge [16]. In fact, the biological effects depend strongly on the PM characteristics. Indeed, it was shown that the size of PM is the crucial parameter which regulated its potential to make an injury, an oxidative, an inflammatory and other biological response [17-18]. The residence time which is the time for which the patient is exposed to aerosols inhalation is also an important factor. More precisely sustained long-time exposure yields to serious cardiovascular, respiratory, and skin diseases. However, short-time exposure can cause morbidity incidents in all ages by cardiovascular and respiratory diseases due to airborne dust particles [19].

It is worth noting that aerosol particles emitted during biomass burning are the most optically active [20] because of their size, in the submicrometer interval, their accumulation mode particles, and their high content of high-absorbing components. Moreover, the biomass burning activities are usually occurring in the underdeveloped countries located in tropical regions such as Africa, East of Asia and the south of America [21]. Indeed, in these regions of world fire is routinely cooking, heating, and also used for deforestation and seasonal burning of cereal straw and pastures. For these reasons, our attention is focused on aerosols and gaseous emissions during pellets combustion in a household boiler of a small power (8-12kW). for this purpose, different samples were prepared by blending lignocellulosic biomasses; olive mill solid/ liquid wastes and pine sawdust in different mass fractions. Even though the ökofen automatic boiler was designed for being fed with woody pellets, we have conducted these combustion tests to assess gaseous emissions such as CO, CO2, CnHmsub> (mainly CH4) and NOx using appropriate gas analyzer. For assessing the aerosol particles an Electrical Low Pressure Induced (ELPI) technique was considered.

Materials and Methods

Different residues from agrifood industry were collected for this study; grape marc (GM) obtained from a winery (Bouargoub, Tunisia), tomato waste (TW) obtained from a concentrate tomato factory (Kairouan, Tunisia), The raw olive mill solid waste (OMSW), the exhausted olive mill solid waste (EOMSW) were purchased from the oil and soap factory of Zouila situated in the region of Mahdia (Tunisia). Also, the olive mill wastewater (OMWW) was collected from the same company. These residues impregnated or not by OMWW were blended with pine sawdust (PS) collected from carpentry of wood (Sayada, Tunisia). During each impregnation test, 20 kg of EOMSW or PS with 10% of moisture (wet basis, w. b.) were added to 100 kg of OMWW characterized by 90% of moisture (W. b.) in a barrel as it was reported in our previous work [22]. The used process to produce different pellets was meticulously described in our previous works [22,23]. The prepared pellets are characterized by an average length close to 3 cm and a mean diameter close to 0.6 cm. Based on the raw material of departure, seven types of samples were produced, namely impregnated exhausted olive mill solid waste (IEOMSW) by OMWW, impregnated pine sawdust (IPS) by OMWW, 100%PS, 100% EOMSW, 100%TW, 50%TW-50%PS and 50%GM-50%PS.

Different analytical techniques respecting European standards were conducted for achieving proximate and ultimate analysis of the prepared pellets. Moisture content was determined by following EN 14774-2 (2010), ash content was determined conformingly to EN 14775 (2010). Nitrogen determination (N) was realized according to EN 15104 (2011) using CHONS elemental analyzer. Chlorine (Cl) and Sulphur (S) contents were estimated following EN 15289 (2011). The technique of Inductively Coupled Plasma-atomic emission Spectroscopy (ICP-AES) was considered for determining the major inorganic elemental analysis according to EN 15290 (2011). The minor element analysis was carried out according to NF EN ISO 16968 (2015). The technique of adiabatic bomb calorimeter (IKA C200) was chosen for the high heating value (HHV) determination, and low heating value (LHV) can be easily deduced by taking into account the latent heat of water evaporation/condensation. The energetic characteristics of each sample’s type can be exhibited via its LHV, its bulk density (BD) and energy density (ED) which is the product of LHV and BD.

Experimental Device and Methods

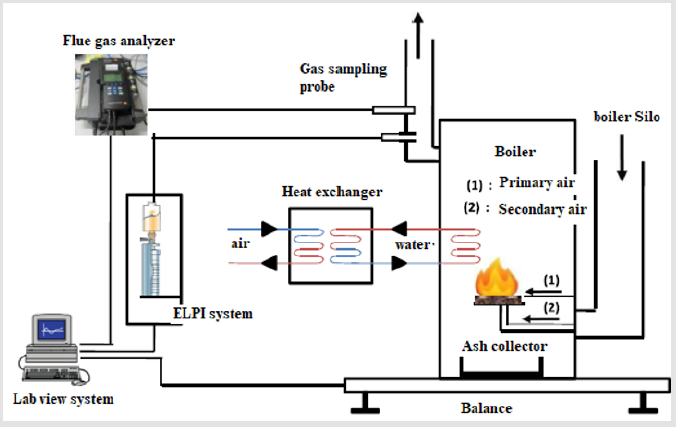

The experimental bench (Figure 2) as well as the experimental protocol was meticulously described in previous works [22-24]. This setup which was designed for laboratory purposes allows to run at different feed levels and to test different types of solid fuels prepared from biomass.

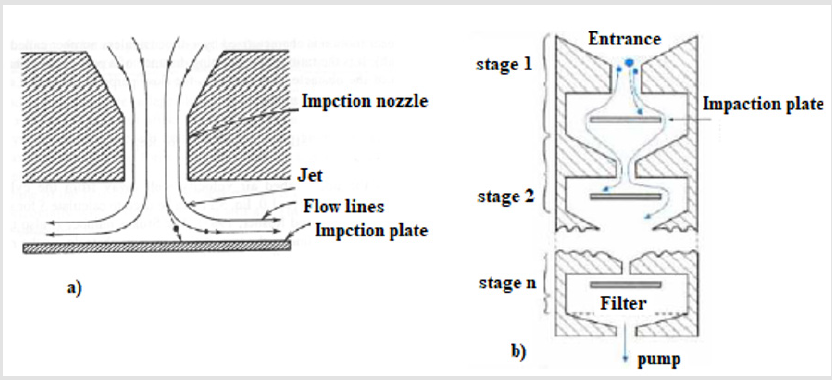

Gaseous Emissions and Aerosols Analyses: The gas analyzer and Physico-chemical based on which it was designed were meticulously described [22-25]. Moreover, an electrical low pressure Impactor (ELPI, Dekati) was used in order to assess the number and the concentration of ultrafine and fine particles, and more precisely characterized by hydraulic diameters ranging between 29nm and 10μm in our case. This technique consists at ionizing the particles according to their Stokes diameter when penetrating the system. Indeed, the aerosols are charged in a positive unipolar particle charger named corona charger. Then, the aerosols penetrated the cascade Impactor in order to be segregated on the basis of their inertia and their aerodynamic diameter as it is illustrated on Figure 3. A multistage electrometer measured the current intensity of the order of femtoampere (1fA = 10-15A) and then system can count the number and the concentration of the charged aerosol particles for each stage using mathematical algorithms.

Hence, the number of aerosol particles is a function of the induced measured current and of the density of the particles in the exhaust gas which has to be given by the user. It is to highlight that aerosol particles number and concentrations were calculated on the basis of using 1g.cm-3 of density value [26]. Moreover, total suspended aerosols (TSAs) were measured following DIN CERTCODIN EN 13229 (2008) certification rules. In order to correlate the aerosols emitted and the pellets characteristics, we realized the so-called principal component analysis (PCA) based on the XLSTAT software. This technique is widely applied in the treatment of high complexity data sets [27]. PCA technique consists at determining the eigenvalues and eigenvectors when treating the covariance matrix of original variables. All this for the goal of finding correlation between variables for which the dimensionality of the data set is significantly reduced. The eigenvalues are the measure of their associated variance.

Results and Discussions

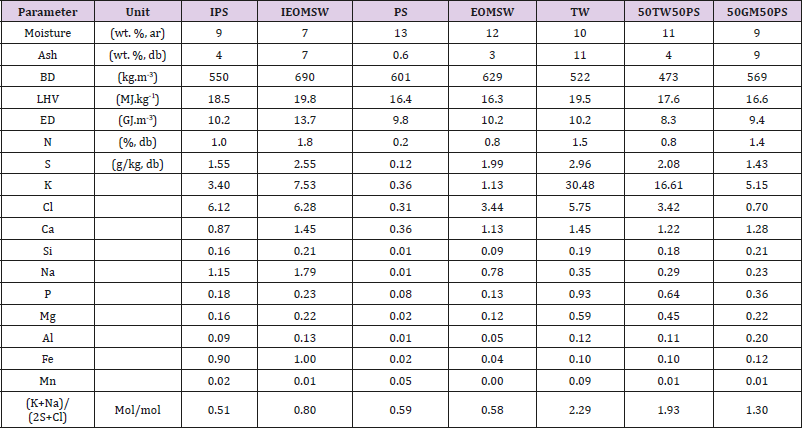

Table 1 shows the ultimate analyses and the proximate analyses of the seven different produced pellets. The moisture contents are ranging between 9 and 13% (wt. %, db). The ash content varies between 0.6 for PS and 11% for TW (wt. %, db). The bulk density varies between a minimum value (522kg.m-3) of TW, and a maximum value of 690kg.m-3 corresponding to IEOMSW. The LHV varies between 16.3MJ.kg-1 of EOMSW and 19.8MJ.kg-1 of IEOMSW. All these values are familiar for researcher in this field and in coherence with what was reported in the literature [28-33]. We noticed that the high ash values for both TW and 50GM-50PS prevent these solid fuels to be conform to the French agropellet standard (<7 wt.%). Also, the French standard couldn’t be reached by TW, 50TW-50PS, EOMSW, IEOMW and IPS due to the chlorine contents (>0.2 wt. %) and sulphur (>0.2 wt. %). As for the nitrogen, it is initially highly presented in the agrifood industry such as olive wastes, grape marc and tomato waste [22]. However, the prepared pellets reach the French agropellet standard (nitrogen content < 2 wt. %), but even with this nitrogen oxide emissions should be seriously considered during combustion tests.

At the bottom of Table 1 we can read, results obtained by ICPAES, the inorganic elements contents. As it is predicted, potassium K, chlorine Cl and calcium Ca are the main elements, whilst Si, Mg, Fe, P and Na are strongly depending on the nature of the biomass.

Table 1: Physico-chemical parameters of the tested pellets.

Note: db: dry basis; ar: as received; BD: bulk density; ED: energy density = LHV× BD

The rest of inorganic elements appear as traces such as manganese Mn and aluminum Al. Due to the impregnation process, we observe that the Na is highly concentrated in the impregnated samples IPS and IEOMSW because the Na content is considerable in OMWW. Besides, as it was suggested by Zeng et al. [34], the sum concentrations of specified inorganic elements are crucial to explain the aerosols emission during combustion. The so-called fuel indexes defined by Zeng et al. [34] and Sommersacher et al. [35] that we calculated in Table 1 under molar ratios (K + Na)/ (2S + Cl) is a crucial parameter governing the PMs (HCl and SO2) emission levels, and the slagging tendency in the bottom ash (not an objective for us in this study). We observe that (K + Na)/(2S + Cl) is equal to 2.3 for TW pellets and is of the same order as woody and herbaceous biomass as it was reported in the literature [34]. This allows predicting that low concentrations of HCl and SO2 are expected in corresponding flue gas.

Combustion Parameters and Pollutant Emissions

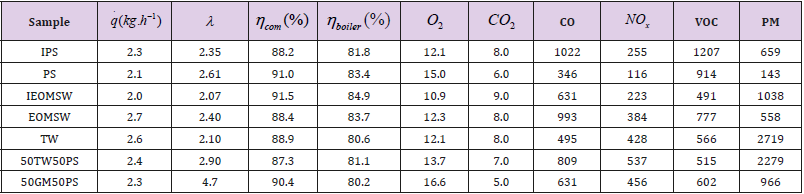

We collected in Table 2 the combustion parameters and the pollutants emissions (gaseous and aerosols) after carrying out combustion tests according to EN 303-5 (2012) standard. For calculations details the reader can refer to our previous work [22]. We notice that the combustion efficiency varies between a minimum value (87.3%) for 50TW50PS and a maximum one (91.5%) for EOMSW. These values are in agreement with what was reported in the literature [28,31-33,36]. Also, it is found in Table 2 that the global boiler efficiency, ranging between 80.2% for GM-PS and 84.9% for IEOMSW, satisfies the minimum value of efficiency (77%) required by EN 303-5 standard. Moreover, TW pellets present the highest aerosols emissions (2719 mg.Nm-3), whereas, PS pellets exhibit the lowest aerosols emissions (143 mg.Nm-3). This result is related to ash content in both pellets, especially as the ash content in TW (11 wt. %) is much higher than ash content in PS (0.6 wt. %). However, the aerosols emissions don’t depend only on ash contents. Indeed, as it is seen in Table 2 the Particulate matter (PM) emissions of 50GM50PS (9 wt. % ash) are lower than 50TW50PS emissions (4 wt. %).

This further was explained by Zeng et al. [34] when building a correlation between the K content as well as the sum (K +Na + S + Cl + Pb + Zn) expressed in mg.kg-1 with PM emissions expressed in mg.Nm-3 when running combustion tests using pellets from Miscanthus, white straw and different mixtures with woody biomass. In addition, the flue gas analysis is a good criterion for aerosol emissions. Indeed, when working under rich combustion (equivalence ratio >1), the CO, the VOC and the PM emissions increase. where, q is the fuel mass flow; λ is the air factor, O2 and CO2 are the average oxygen and carbon dioxide proportions in the flue gas (vol. %); η is the efficiency (%); CO, NOx, VOC and PM are the concentrations of carbon monoxide, nitrogen oxides (NO + NO2), volatile organic compounds CnHm and aerosol particles, they are all expressed in mg. Nm-3 at 10 vol. % O2.

Distribution of PM Emissions

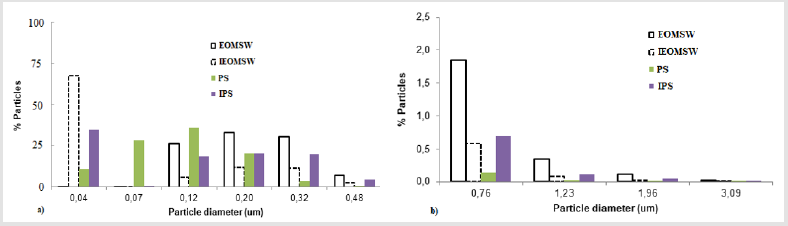

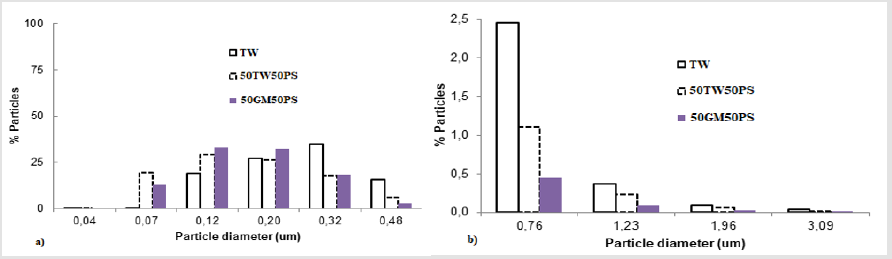

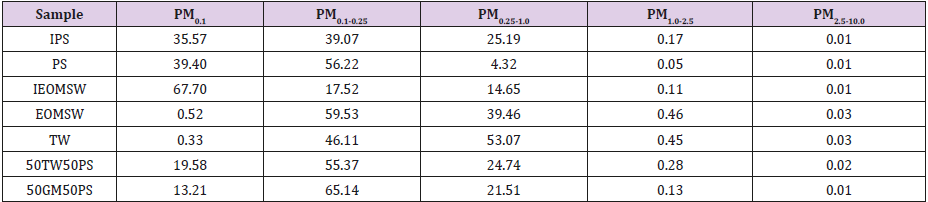

The aerosol particles were distributed according to their hydraulic diameter. They can be described by their number or their percentage as it is reported in Table 3. We notice From Table 3 and Figures 4 & 5 that about 99% in number of aerosols correspond to fine sub-micron particles characterized by a diameter lower than 1μm. This observation is in agreement with result reported by Johansson et al. [37] when studying combustion of wood pellet briquettes. Moreover, Figure 4 shows that the blending operation using PS and the impregnation process using OMWW favorites the nanoparticle emissions with a diameter less than 0.1μm. More precisely, as it is exhibited in Table 3, the impregnation process of PS shows that percentages of both PM0.1-0.25 and PM1.0-2.5 decreases, whereas, the percentage of PM0.25-1.0 increases, but, no effect is mentioned for PM2.5-10.0. However, the impregnation of the EOMSW by OMWW shows a different behavior. Indeed, the percentage of PM0.1 was highly increased, whereas, the percentages of respectively; PM0.1-0.25, PM0.25-1.0 and PM1.0-1-25 were highly decreased.

Figure 4: PM percentage distribution versus particle diameter (d) during EOMSW, IEOMSW, PS and IPS pellets combustion. a) For d<0.5μm and b) for 0.7<d<3.1μm.

Figure 5: PM percentage distribution versus particle diameter (d) during TW, 50TW50PS and 50GM50PS pellets combustion. a) For d<0.5μm and b) for 0.7<d<3.1μm.

These observations are may be attributed to two causes. First the PS pellets are expected to generate an important percentage of nanoparticles (39.4%) during combustion as it is shown in Table 3. Second, the impregnation process increases the nanoparticle generation (Table 3) due to the addition of minerals present in OMWW (Table 1). These minerals may play a catalytic role during the fractioning of the soot agglomeration or condensable organic vapours. These assumptions are in agreement with the observations of Garcia-Maraver et al. [33]. Also, Sommerrsacher et al. [35] have found a correlation between the sum (Na + K) content and aerosols of diameter equal to 1μm named PM1 during the combustion tests realized on different samples. This correlation is linear with a regression factor R2 = 0.94. Also, in the same context Jeguirim et al. [38] have shown a linear correlation between the total PM (g/kg) and K and the sum (K + Na + S +Cl) expressed in g/kg. Furthermore, they found that the correlation with potassium is more strong with a correlation coefficient R2 = 0.94 than with the sum (K + Na + S +Cl) for which R2 is equal to 0.88.

In agreement with our study showing important percentages of PM0.1-2.5 for all samples, it was proven in the literature that these PM affects seriously lungs [39]. This attack is due to the contact of toxic chemical PM on the epithelium of human lung airways. These PM are generated by combustion fossil fuels, vehicle exhaust and industrial process acid, as well as volatile organic compounds such as pathogens, fungi and pollens. This problem was most accentuated for humans working in the industries of sandblasting, flint mild and the soap manufacturing. Indeed, the inhalation of asbestos for example causes directly asbestosis, and what is dangerous is that silicosis and asbestosis are incurable and even when the exposure stop the health degradation may still progress [40]. On the other hand, it is well known that the blood brain barrier protects the brain, but this latter may not operate properly and then doesn’t protect the brain from PM. It was proven that various toxic effects including respiratory, cardiovascular and neurological toxicities can be caused by PM and particularly PM2.5 can easily cross the blood brain barrier.

A specific study showed that patients exposed to coal fumes are subject of an increase incidence in ischemic stroke which is the main cause of death in Shanghai for example [41]. Nevertheless, by referring to Table 3 we can say that there is no fear in our case because the percentage content of PM2.5 is not elevated (lower than 0.5%). Moreover, it was reported in the literature that aerosols with diameters less or equal to 2.5μm was linked to many risks of cardiovascular diseases [42,43]. More deeply, these problems are due to variation of the blood composition include the irregularity of the heart rate, plasma viscosity and blood pressure regime. Also, with the increase of PM concentration the risk of myocardial infraction increases too [42,43].

Conclusion

The combustion of the biomass either at raw state or densified biofuel is always at the origin of the gaseous and PM emissions. We find in the present study that the gaseous and the PM emissions are strongly depended to the nature of the different tested pellets. Also, it was demonstrated that the combustion parameters affects strongly the gaseous and the PM emissions. Moreover, the PM distribution exhibits that the highest concentrations are met with PM0.1-0.25, and PM0.25-1.0 respectively. For these particular PM sizes, serious harmful problems are to be taken into consideration including lungs, brain and heart.

Acknowledgement

The author would like express his deep thanks to Professors Lionel limousy and Mejdi Jeguirim from IS2M of Mulhouse for their precious technical supports.

For more Articles: https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.