The CAD/CAM Method is More Efficient and Stable in Fabricating of Lingual Retainer Compared with the Conventional Method

Introduction

The shortage of orthodontists and orthodontic technicians are the worldwide issue [1-3]. There are several reasons for this issue. First, the systematic labor shortage makes the total number of orthodontic and orthodontic technician number limited. In the U.S., it is expected to transform the workplace over the next 15 to 20 years as the gap between baby boomers and entrants of collegeeducated workers widens due to the boomers’ mass retirement [2]. It was estimated that by the year 2020 one out of every two people in the U.S. will be older than 50. Second, the long-term basic knowledge studying, and clinical training make the number of orthodontists and orthodontic technician limited. Third, the geographic distribution of specialist orthodontists and orthodontic providers are regional inequalities. Study result from Japan showed that medical access to specialist orthodontic services might be limited in areas other than urban districts and the regional inequalities of specialist orthodontists are high [3].

The computer-aided designed and manufactured (CAD/CAM) technology is wildly applied in the biomedical science and oral and dental science that provides the stable and efficient way to treat common and severe disease [4-6]. The digital method could offer a stable method not matter for some simple cases or for some severe and complicated cases. For bone tissue regeneration, 3D-printed scaffold exhibited excellent biocompatibility which was suitable for mesenchymal stem cells grow and differentiate and offered the appropriate mechanical property which was like its natural environment [7]. In the orthodontics, the CAD/CAM was used to fabricated not only the labial bracket system, but also lingual orthodontic bracket appliance [4]. In the prosthodontics, CAD/CAM was able to print removable partial denture but also customized CAD/CAM implants for complex craniofacial reconstruction in children [6,8]. Lingual retainer is bonded to the lingual side of upper and lower incisors. The bonded retainers are today a standard of care, especially in the mandible [9]. Renkema et al. found that 97% of all Dutch orthodontists utilize fixed retainers [9]. But the process to bend the lingual retainer is a time consumer, which is usually fabricated by flexible spiral wire. In this study, we planned to compare the time-consuming and stability between conventional method and CAD/CAM method in fabricating lingual retainer.

Methods

Comparison of the Conventional and CAD/CAM Fabrication Process

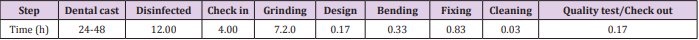

For the conventional method, the patient’s dental cast should be taken and sent to the laboratory. And it must be regularly disinfected and checked in. After grinding the cast, the lingual retainer will be designed and bent by an orthodontic technician. And the lingual retainer will be fixed by silicone rubber. And then it will be cleaned and has a quality test. And it will be disinfected again and outgoing checked. For the CAD/CAM method, the digital dental cast was obtained by a 3shape D900 digital scanner. And the lingual retainer was designed by the 3shape software and fabricated by a high-speed milling machine in titanium alloy. And the lingual retainer also will be fixed by silicone rubber, cleaned, and after it has a quality test, it will be disinfected again and outgoing checked.

Comparison of the Manual Handling Time in Laboratory Between Conventional and CAD/CAM Method

In order to equal the sample, five dental casts were obtained, and 4 copies of each cast were prepared for lingual retainer manufacture. Each technician had five dental casts for conventional lingual retainer bending and another five same copies for CAD/CAM lingual retainer fabrication. While some steps of the two process in the labor were similar, we compared the manual handing steps of the two methods in the laboratory which were the main difference of two methods and also the main time-consuming part. For the conventional method, the main manual handing part was the wire bending and for the CAD/CAM part was the designing. So, we asked two sophisticated orthodontic technicians who had work in the laboratory for orthodontic appliance fabrication for more than 3 year to bend the wires for the 5 dental casts and design the retainer in the 3-shape software individually. And we record the time.

Statistically Analysis

Data are presented as mean±SD. Statistical analyses were performed using one-way analysis of variance and a value of P <0.05 was considered statistically significant.

Results

The Total Time Cost by the Conventional and CAD/CAM Method

The conventional method contained 9 steps (Table 1) which was quite time-consuming and complicated, compared to the CAD/CAM approach which contained 6 steps (Table 2). Regularly, the conventional method might consume 24.727 hours to 36.727 hours (Table 1), while the CAD/CAM method only costed 2.91 hours (Table 2). And the manual handing steps of the digital method in laboratory was simpler than the conventional method (Figure 1).

Figure 1: The manual handing steps in laboratory of the digital method in fabricating the lingual retainer.

The Time-Consuming of the Manual Handing Steps in Laboratory in Fabricating Lingual Retainer with Conventional and Digital Method

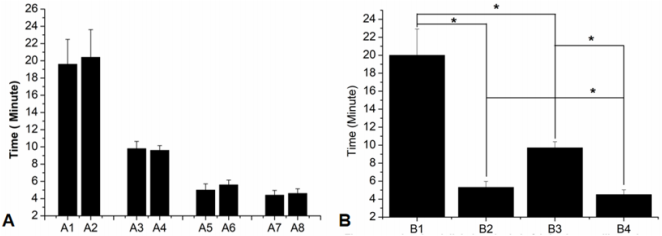

First, we compared the two sophisticated orthodontic technicians in fabricating maxillar and mandibular lingual retainer with conventional and digital method (Figure 2A). There is not significant between the two technician in bending maxillar lingual retainers (A1= 19.6±2.88, A2= 20.4±3.20 ) with conventional method, in bending the mandibular lingual retainers (A2= 9.8±0.87, A2= 9.6±0.55) with conventional method, in fabricating the maxillar lingual retainers (A5= 5.0±0.71, A6= 5.6±0.55 ) with digital method, and in fabricating the mandibular lingual retainers (A7= 4.4±0.55, A8= 4.6±0.55) with digital method. All of these indicated the consistency of the data obtained from this study. Second, we compared the maxillar and mandibular lingual retainers bent with conventional methods or fabricated with digital method by the sophisticated technicians (Figure 2B). The results showed that no matter for the maxillar lingual retainer or the mandibular lingual retainer, the digital method (B2= 5.3±0.67, B4= 4.5±0.53) was significantly faster than the conventional method (B1= 20.0±2.91, B3= 9.7±0.67). These data exhibited that the digital method was powerful in deal with the issue of shortage in orthodontic technicians.

Third, the different time-consuming of maxillar and mandibular lingual retainers manufactured by conventional and digital methods showed that the maxillar lingual retainer consumed more time than the mandibular lingual retainer no matter by the conventional (Figure 2B) (B1= 20.0±2.91, B3= 9.7±0.67) or digital method (B2= 5.3±0.67, B4= 4.5±0.53). The significantly different time-consuming between bending the maxillar and mandibular lingual retainer was might be due to that it was more difficult to bend the maxillar lingual retainer than bend the mandibular lingual retainer with conventional method, because that the difference of morphology among the maxillar upper incisors were more notable than the mandibular lower incisors.

Figure 2: Time consuming.

A. Different Technicians Fabricating Maxillar and Mandibular Lingual Retainers with Different Methods. (A1,A2 :Technicians fabricating the maxillar lingual retainers by conventional method; A3, A4:Technicians fabricating the mandibular lingual retainers by conventional method;A3,A4:Technicians fabricating the maxillar lingual retainers by digital method; A3,A4:Technicians fabricating the mandibular lingual retainers by digital method).

B. The conventional and digital methods in fabricating maxillar and mandibular retainers. (B1 and B3: Bending maxillar and mandibular lingual retainer by conventional methods respectively; B2 and B4: Fabricating maxillar and mandibular lingual retainer by digital methods respectively).

Discussion

Until the digital technique has fast developed and wildly applied, the lingual retainer wire technology has almost not significantly change over the past 40 years [10,11]. The thin (0.0195 or 0.0215 in) multistranded wire bonded to the incisors and canines and the thick (0.025 to 0.032 in) round stainlesssteel wire bonded only to the canines are the two lingual retainers mainly used in daily orthodontic practice. With the development of digital technology, the lingual retainer has a rapid growth, because the lingual retainer was more convenient to apply the digital technique than the removable retainer such as Harley retainer. For example, the “Memotain” was introduced recently, which was a CAD/CAM nickel-titanium lingual retainer [10]. There are kinds of advancements in CAD/CAM technology such as offering the digital impressions which reduced the time consuming steps to include tray selection, dispensing and the transforming of the impression to the laboratory, offering the digital models which eliminated of polymerization shrinkage of the impression, and offering the virtual articulators and face bows which is less time-consuming than using the physical face bow [12-14].

In the study, we showed that the digital method was faster in fabricating maxillar (B2= 5.3±0.67) and mandibular (B4= 4.5±0.53) lingual retainer than the conventional method in fabricating maxillar (B1= 20.0±2.91) and mandibular lingual retainers(B3= 9.7±0.67). The digital method is more stable than the conventional method in fabricating the lingual retainer, which was not disturbed by the individual differences or morphological differences of oral tissue or teeth as much as the conventional method [14,15]. The morphological differences among the maxillar upper incisors were more notable than the mandibular lower incisors. In these studies, the different time-consuming in bending the maxillar lingual retainers with conventional method (B1= 20.0±2.91) was as much as twice the time in bending the mandibular retainers (B3= 9.7±0.67). While there was significantly different time-consuming in fabricating the maxillar (B2= 5.3±0.67) and mandibular lingual retainer (B4= 4.5±0.53) with digital method, but the difference was less than 10 percent. All these results suggested that the CAD/CAM is more efficient and stable in fabricating lingual retainer than the conventional method.

Conclusion

a) The CAD/CAM method saves much time and is an efficient method in fabricating lingual retainer than conventional method.

b) The CAD/CAM method is more stable in fabricating the lingual retainer, which is not disturbed by individual and morphological difference so much as the conventional method.

For more Articles: https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.