Effect of Hydrothermal Treatment on the Yield and Quality of Spelt Flour

Introduction

Spelt refers to non-traditional types of plant raw materials, promising for expanding the range of healthy foods, as well as for the manufacture of food additives for functional purposes, including biomodified spelt flour and biomodified spelt cuts [1]. A promising and relevant direction of scientific research is the use of methods of biotechnological impact on spelt processing products with the production of food products for general, functional and therapeutic and prophylactic purposes [2-9]. Spelt grain is superior to wheat, rye and triticale in terms of protein, essential amino acids, vitamins, macro- and microelements, biologically active substances. Spelt flour is limited to lysine and threonine, but it contains lysine 1.7 times more than in wheat baking flour [3]. The protein content in spelt grain is 5% higher than in wheat grain. A sufficiently high protein content makes spelt a valuable source of vegetable protein for the production of various foods based on its processed products. This is especially true in view of the lowcalorie content and imbalance of the diets of the majority of the population of our country [10]. At the same time, a significant drawback of the unpretentious to the conditions of growing cereal culture of spelt is the difficulty of its threshing and subsequent post-harvest processing. The fact is that the grain of spelt, unlike wheat grain, is not completely ground from the ear, but together with the flower and spike shells attached to it, as a result of which certain difficulties arise in the processing of grain into baking flour. It is in connection with this drawback, as well as in connection with low yields, that drought- and cold-resistant spelt has now been replaced by new varieties of high-yielding holozer wheat, more demanding than ordinary spelt, to soils, climate and other growing conditions. Consumption of such a useful crop as spelt is unreasonably low, which is largely due to the limited scientifically based technologies for its processing and the range of products from its processing. The purpose of the research is to determine the optimal parameters of hydrothermal processing of spelt grain in the production of baking flour.

Research Materials and Methods

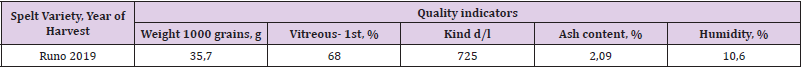

In experimental studies conducted at the Department of Grains, Bakery and Confectionery Technologies of the Federal State Educational University of Higher Educational Enterprise “Moscow State Unitary Enterprise”, I.S. Turgenev State University of Higher Learning and Federal State Educational Enterprise “N.V. Parakhin OsAU”, spelt of the Runo variety of the 2019 harvest grown in the Oryol region was used as an object of research to achieve this goal. A distinctive feature of the object of research was that the original grain of spelt was passed through a peeling machine with the removal of 10% of the flower and seed membranes. Baseline indicators of the quality of the original spelt grain are presented in Table 1. Grinding of the original spelt grain was carried out on grinding and sorting units MLP-4 with rifled rollers and MLP-4 with smooth, microrolling rollers. Sieving of intermediate grinding products was carried out in laboratory sieving for 90 seconds. The parameters and modes of grinding corresponded to the recommended “Rules for the organization and conduct of the technological process at flour milling enterprises” operating in the Russian Federation. The strip systems use grooved rollers with a grooved back along the back. All grinding and grinding systems use roller machines with micro-rolling rollers. The modes of grinding spelt grain on the I drednaya system are 25-30%. Due to the fact that the initial grain of spelt was peeled, the total extraction of intermediate grinding products on I-III draught systems was increased and amounted to at least 85%. The extraction mode on 1-3 grinding systems is at least 50%. The whiteness of spelt flour was determined according to GOST 26361-2013, ash content according to GOST 27494-87, humidity according to GOST 13586.5-2015.

Results and Discussions

Cold conditioning was used as a TGT, as the most common method. To study the effect of hydrothermal treatment (GTO) on the yield and quality of spelt baking flour, the initial peeled grain of spelt was moistened to a process humidity of 16-16.5% and served, respectively, 2, 4, 6, 8 and 10 hours. The technological scheme for processing spelt grain into baking flour was based on a patented method for producing flour from triticale grain [11]. The technological scheme of grinding the peeled grain of spelt consisted of 4 dredged (other vessels), 5 grinding (r.s.) and 1 grinding system (ext.s.). The ripped process of the scheme of processing spelt grain into baking flour consists of a stage of cereal (I-III striped systems) and a stage of grinding (IV stripe system). When grinding the original peeled spelt grain, the mechanical and kinematic parameters of roller machines with rifled and microsched shafts, sieving schemes, the dimensions of both flour sieves and the dimensions of the sieves for sifting intermediate grinding products remained unchanged. After the end of each grinding of spelt into baking flour, all the streams of flour were weighed, and the grinding balance was made. Next, the ash content, humidity and whiteness of each stream (a total of 10 streams of spelt flour) were determined. Based on the results of the obtained data on the quality indicators of flour flows, the weighted average ash content and whiteness of spelt flour were calculated, and cumulative ash and whiteness curves were constructed. The process of grinding and forming the quality of flour from the peeled grain of spelt is shown in the form of cumulative ash curves (Figure 1). The presence of 2 stages of flour formation during grinding of spelt grain according to the developed technological scheme was established, which is quite clearly seen from the graphs of cumulative curves of spelt flour.

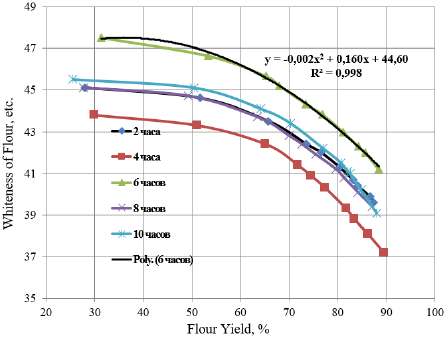

The first stage in the formation of spelt flour consisted in the extraction of the central part of the endosperm with an output of 70-72% and an ash content of 0.77-0.85%. At the second stage of the formation of spelt flour occurs due to the extraction of the peripheral part of the endosperm and the subaleuronic layer with an output of 15-20% and an ash content of 0.85-1.01%. Analyzing the cumulative whiteness curves (Figure 2), it was revealed that the weighted average whiteness of spelt flour is higher at 6 hours of agitation of the original grain and is 41.2 units of the device. When the initial grain of spelt is 4 hours, the lowest weighted average whiteness of spelt flour is established, which is 37.2 units of the device [12].

Conclusions and Recommendations

1. The optimal time for peeling off the flaky grain of spelt sent for processing into baking flour is 6 hours.

2. When grinding the peeled spelt grain into baking flour, the total yield of spelt flour was 87.4-90.0%, depending on the spelt time from 2 to 10 hours, while all spelt flour obtained in all 5 modes of hydrothermal treatment corresponded to 1 grade of spelt flour.

3. The obtained results can be recommended for use in the construction of a flour mill when calculating bunkers for the removal of spelt grain entering for processing on the roll machine of the I dredal system.

For more Articles on: https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.