Processing of Soybean Meal and Cake into Flour and Bran

Introduction

Soybeans are the most common leguminous crop in the world. It has long been cultivated in the countries of Southeast Asia: China, India, Japan, Korea, Vietnam, Indonesia. Due to its climatic stability, soybeans have been widely distributed outside their original range and are now cultivated in more than sixty countries. The increase in the production of soybean seeds in the world is mainly due to the expansion of the sown area and, to a lesser extent, by increasing yields [1-5].

Nutrition experts define soy as the ideal food for humans. It is assumed that in the middle of the 21st century, more than half of the total volume of soybean seeds produced will be used as raw materials for food production. Soy attracts everyone’s attention not only for its high concentration and usefulness of protein, but also for its economy [5-10]. Vegetable soy and animal proteins are interchangeable in both quantitative and qualitative amino acid composition, close to beef meat proteins. At the same time, the digestibility of soy proteins reaches about 70%. Soy is not only proteins, it contains minerals necessary for the human body: potassium, sodium, calcium, iron, zinc, as well as vitamins of group B and C. Soy products are characterized by the absence of cholesterol, semi-saturated fatty acids and low calorie content [10-14].

Soybean meal is a secondary product of the oil extraction industry in the production of oil from soybean seeds by chemical extraction. Soybean meal is the most popular type of meal in the world. Its production volume in the world reaches about 130 million tons. Soybean meal has found wide application as the main protein additive to the feed of farm animals and in the production of various food products. The purpose of this research is to develop a technology for processing soybean meal and cake into flour and bran by mechanical means.

Research Materials and Methods

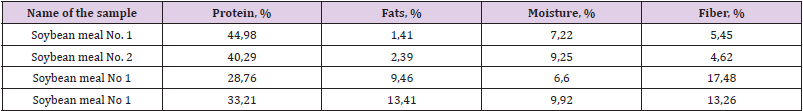

In the studies conducted at the Department of Grains, Bakery and Confectionery Technologies of the Federal State Budgetary Educational Institution of Higher Education “MSUPP”, experiments were conducted on the separation into anatomical parts of the initial samples of soybean meal and soybean cake by mechanical means using a roller machine. The object of the study was two samples of soybean meal and two samples of soybean meal with different content of protein, fiber and fat, obtained from two different enterprises. Table 1 presents the chemical composition of the presented samples of soybean meal and cake as objects of study.

Grinding of the initial samples of soybean meal and soybean cake was carried out at the laboratory grinding mill MLP-4 with rifled rollers. The main mechanical and kinematic indicators of the mill MLP-4 are as follows: productivity - up to 100 kg / h, speed of fastrotating roller 5.0 m / s, differential 1.5, arrangement of grooves - back on the back, number of grooves on the 1st running centimeter - 8 pieces, slope of grooves 7%. The developed technological scheme for processing soybean meal and cake into flour and bran consists of only 3 grinding systems. Modes and parameters of grinding on roller machines for all samples of soybean meal and soybean meal remained unchanged. Sifting of intermediate products of soy meal and soybean meal grinding and flour sowing was carried out at the sieving of the MLP-4 mill, consisting of a set of 3 sieves, including 2 grits and one flour sieve.

The chemical and physicochemical parameters of the initial samples of soybean meal and cake, as well as the fractions of soybean flour and soybean bran obtained after grinding, were determined on the infrared grain and flour analyzer OF the INFRALUM® FT-12 (manufactured in Russia).

Results and Discussion

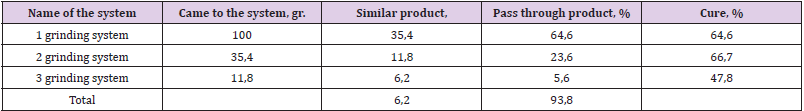

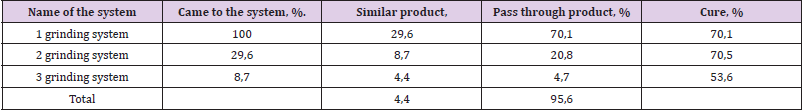

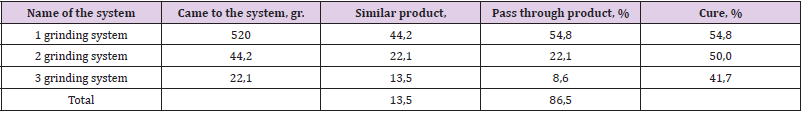

At the first stage of research, grinding of the initial samples of soybean meal and cake was carried out to obtain flour and bran at the MLP-4 laboratory grinding mill with rifled rollers to determine the potential flour milling properties. The data obtained are presented in tables 2-4. As can be seen from Table 2, the total yield of soy protein flour was 93.8%, and the yield of soy bran was 6.2%. The yield of the highest protein fraction of soybean flour was 64.6%, and the yield of the lowest protein fraction of soybean flour was 5.6%. As can be seen from Table 3, the total yield of soy protein flour was 95.6%, and the yield of soy bran was only 4.4%. The yield of the highest protein fraction of soybean flour was 70.1%, and the yield of the lowest protein fraction of soybean flour was 4.7%. As can be seen from Table 4, the total yield of soy protein flour was only 86.5%, and the yield of soy bran was 13.5%. The yield of the highest protein fraction of soybean flour was 54.8%, and the yield of the lowest protein fraction of soybean flour was 8.6%.

Table 2: Yield and extraction of soybean flour for all technological systems in the processing of soybean meal No. 1.

Table 3: Yield and extraction of soybean flour for all technological systems during the processing of soybean meal No. 2.

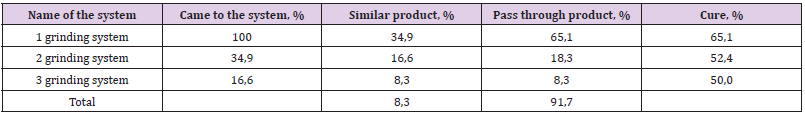

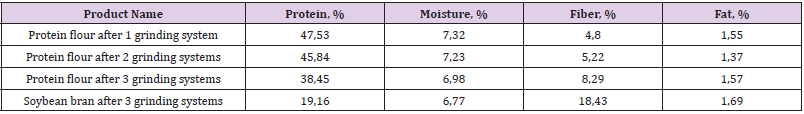

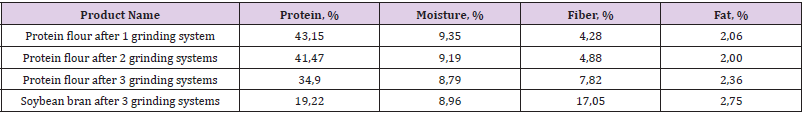

As can be seen from Table 4, the total yield of soy protein flour was 91.7%, and the yield of soy bran was 8.3%. The yield of the highest protein fraction of soybean flour was 65.1%, and the yield of the lowest protein fraction of soybean flour was 8.3%. At the second stage of research, the chemical composition of the initial samples of soybean meal and cake and the products of their processing obtained on a roller machine from all technological systems was determined (Tables 5-8). The chemical composition of the initial samples of soybean meal and cake, as well as those obtained from them as a result of mechanical processing of soybean flour and soybean bran, are presented in tables 6-9. As can be seen from Table 6, the protein content in the highest protein fraction of soybean flour was 47.53% with a yield of 64.6%, and the protein content in soybean bran was 16.16% with a yield of 6.2%. As can be seen from Table 7, the protein content in the highest protein fraction of soybean flour was 43.15% with a yield of 70.1%, and the protein content in soybean bran was 19.22% with a yield of 4.4%.

Table 4: Output and extraction of soybean flour for all technological systems during processing of soybean cake No. 1.

Table 5: Output and extraction of soybean flour for all technological systems during processing of soybean cake No. 2.

Table 6: Chemical composition of the initial sample of high-protein soybean meal No. 1 and products of its processing.

Table 7: Chemical composition of the initial sample of high-protein soybean meal No. 2 and products of its processing.

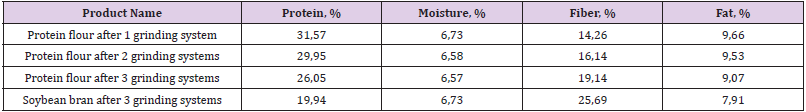

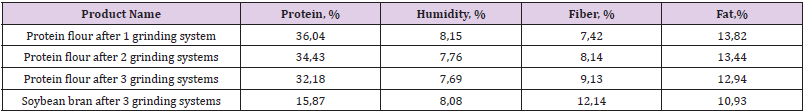

As can be seen from Table 8, the protein content in the highest protein fraction of soybean flour was 31.57% with a yield of 54.8%, and the protein content in soybean bran was 19.94% with a yield of 13.5%. As can be seen from Table 9, the protein content in the highest protein fraction of soybean flour was 36.04% with a yield of 65.1%, and the protein content in soybean bran was 15.87% with a yield of 8.3%. Analyzing the data obtained from Tables 6-9, it can be seen that the processing of soybean meal into flour and bran occurs with greater efficiency compared to the processing of soybean meal. This is due to the fact that the original soybean meal has an increased fat content of up to 13. %, which prevents the effective separation of the original cake into flour and bran.

Table 8: Chemical composition of the initial soybean sample cake No. 1 and products of its processing.

Table 9: Chemical composition of the initial soybean sample cake No. 2 and products of its processing.

Findings

Based on the results of the studies, it is possible to draw conclusions about the excellent flour milling properties of all the presented samples of soybean meal and cake. The yield of soy protein flour ranged from 86.5 to 95.6%. It is established that the processing of soybean meal into flour and bran occurs with greater efficiency compared to the processing of soybean meal. This circumstance is due to the fact that in the original soybean cake there is an increased fat content of up to 13%,” which prevents the effective separation into flour and bran during the processing of the original cake. It is worth noting that during the processing of soybean cake, clogging (salting) of the cuts of the grinding rollers occurs, which can lead after a short period of time to a decrease in the yield of flour, the productivity of the mill and a deterioration in the quality of the finished product. In addition, sieves are clogged (salting occurs) in the sieve when sieving intermediate products of soy cake grinding. It is necessary to clean the sieves after each system. Thus, the processing of soybean cake into flour and bran is impractical due to the increased oil content.

For more Articles on: https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.