Newer Technologies, Better Healthcare

Introduction

Modern approach to healthcare is largely mediated by economic factors since public health budget is in constant growth in all the Western nations. The aging of the population also increases the minimum needs and the hospital admissions rate [1]. Many possible solutions have been proposed to face this big problem from every possible side: for example, food awareness campaigns, mass vaccinations, diagnostic screening by age group. Every large scale initiative sees its effectiveness greatly reduced by the intrinsic limits of traditional medicine, based almost exclusively on clinical practice supported by statistical studies and on pharmacological chemistry [2]. The next revolution in medicine, and more generally speaking in healthcare, will come from innovative technologies acquired from very different field of applications, such as large electronic consumer and telecommunication, and adapted to specific problems [3]. In particular, micro- and nanotechnologies, i.e. systems and devices having dimensions under 10-6 m, are driving the development of new products more performing than the existing ones. Scaling down the size of common materials, both the organics and the inorganics, it is not only matter of fabrication ability, but it opens the way to a completely diverse world where things behave different [4]. In some cases, the matter properties drastically change on the nanoscale. Crystalline silicon, the basic material in electronic, is not light emitting and can cause silicosis, a pulmonary disease, whereas its nanostructured counterpart, the porous silicon, is photoluminescent and completely biodegradable; carbon is highly insulating, since it has a very large bandgap, while carbon nanotubes and graphene are highly conductive; and the list of examples could continue for a long. In other cases, such as the one of popular microfluidics, geometrical features matter more than bulk properties.

As a matter of fact, when linear dimension (L) decreases, surface interaction scale more slowly (as L-2) with respect to volume (as L-3), so that surfaces are more important than volume. There is also another big obstacle that delays the advancement of more efficient practices in medicine due to the intrinsic difficulty of translating laboratory science into industrial production. Most of the scientific discoveries found in the academic habit is lost in a “Death Valley” before industry could get advantages from them. In this view, technology transfer companies play a strategic role in overcoming the gap between scientific research and industrial development. In South Italy, Materia’s Srl is one of the most active start-up company highly specialized in technology transfer. In this perspective paper, we will focus on two specific systems, developed in collaboration with academic institutions, that are explicative of brand new technologies applied to human healthcare, the polymeric microneedles and the peptide functionalized nanoparticles.

Observations

Drug delivery is a hot topic in translational medicine, since it involves pharmacokinetics and pharmacodynamics, which are related to when, where and how an active molecule goes and works in the human body. Moreover, drug delivery can be systemic, i.e. drug injected in blood, or local, when the drug is delivered in a specific site. New technologies are available for both methodologies [5,6]. The dermis is the thickest component of the skin, up to 4mm in depth. Its upper layer, the 100-200μm thick papillary dermis, consists of thin collagen bundles, elastin fibers, fibrocytes. There is also water, electrolytes, plasma proteins and polysaccharides– polypeptide complexes. Below this layer is the reticular dermis, made up of thick collagen bundles and coarse elastic fibers. Although the stratum corneum (SC) is the major contributor to the barrier properties of the skin. The thickness of the SC varies throughout the body. In the palms of the hands and the soles of the feet (sometimes knees, elbows, knuckles,) this layer is stabilized and built by the stratum lucidum (clear phase) which allows the cells to concentrate keratin and toughen them before they rise into a typically thicker, more cohesive SC. In general, the stratum corneum has a thickness between 10 and 40μm. Only compounds which are able to get into the SC, diffuse through living epidermis and pass through the upper part of the papillary dermis has the potential to reach circulation and exhibit systemic effects [7].

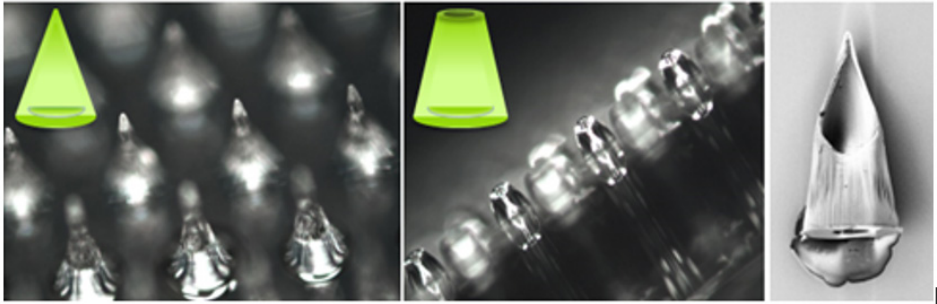

Biodegradable and biocompatible MNs could be used for local drug delivery [8]. Materia’s Srl has patented two technologies for fabricating MN by using a photolithographic approach. These devices can be added with a porous silicon free-standing membrane, using, for example, polyethylene glycol (PEG) or other biodegradable polymers and a commercial photo-catalyzer [9,10]. In Figure 1 are reported the sketch and the optical images of pyramidal MN, conical hollow MN and a detailed micro-photo of a hollow MN realized by a scanning electron microscope. Transdermal MNs create micron sized pores in the skin to enhance delivery of the drug across the skin. MN are ideal for patient adherence as they do not stimulate nerves that are associated with pain. MN improve patient compliance as patient with needle phobia will be more likely to apply the patch because of its painlessness. Additionally, patients can administer the drug by themselves. The porous MNs not only increase the storage of a relevant amount of the drug, but also offers a continuous, naked-eye monitoring of the drug delivery process.

Figure 1: Schematics and images of polymeric MN: pyramidal shaped, conical shaped and hollow. Last image is highly detailed image of hollow MN realized by a scanning electron microscope.

Polymeric hollow MNs (HMNs) could be used for the transdermal administration of active molecules and/or for the sampling of biological fluids. Pressure, and thereby flow rate, can be changed in HMNs for a rapid bolus injection, a slow infusion or a varied delivery rate. HMNs can also be used to administer a larger dose of drug solution. MNs are mechanically strong to penetrate skin, increasing the permeability of encapsulated drug through skin. Moreover, the drug release from MNs, can be thermally activated, through the variation of the permeability. The drug diffuses from the drug reservoir (MNs back-plate) via the MNs into the skin. Systemic delivery of drugs suffers, both in case of oral administration or of blood injection, strongly suffers from human body response. The pills ingested are seriously degraded by acid environment in the stomach and the efficacy of the active principle contained in the pills depends on enteric absorption. On the other hand, molecules in the blood must face more than 8000 proteins, enzymes and other components that easily neutralize the active substance. Nano-formulation of drugs is the technological way to overcome these intrinsic difficulties. In this field, Materia’s Srl has patented one Nano-system of proved antimicrobial activity [11]. The nanocomplex is made of a small synthetic peptide, derived from bovine immune system, covalently bioconjugate to small hybrid gold nanoparticles [12]. This Nano systems has been proved to be strongly active against human pathogens in very low concentration, i.e. in the sub micromolar range [13,14].

Nanomedicine has been recently defined as a specific subset of nanotechnology, in particular, as the detection, repair, construction and control of human biological systems at the molecular level, using engineered nanodevices and nanostructures. The two examples exploited by Materia’s Srl by developing two industrial products from laboratory proof-of concept to pre-production level, clearly demonstrated that the next future of medicine, and in a larger view also of the entire healthcare system, will be based on the application of innovative technologies to specific biological and medical problems. Nanotechnologies are changing the world as we are used to know it, favoring the large distribution of diagnostic, therapeutic and life saving devices, with performances comparable to those of laboratory instrumentation. The health market requirements push for faster and newer class of devices based on nanotechnologies that are continuously developed in academic laboratories all over the world. This is the reason why there is also the need of technology transfer societies which help innovation to go from laboratories up to the final users, increasing the quality of life of everyone.

Cytomechanical Alterations Induced by Inorganic NPs-https://biomedres01.blogspot.com/2021/03/cytomechanical-alterations-induced-by.html

More BJSTR Articles : https://biomedres01.blogspot.com

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.