Orthopedic Implants: Coating with TiN

Introduction

Aiming for a better quality of life of the patient the development and improvement of orthopedic implants have been extensively investigated. One of the factors that distinguish these biomaterials from any other material is the ability to be in contact with tissues of the living organism and not cause adverse reactions to it or without causing an unacceptable degree of damage to that body [1]. Some properties are required by these biomaterials. It is known that the presence of body fluids allows metal implants to release metallic ions that may accumulate in nearby tissues or be transported to other parts of the body. Corrosion is one of the major processes affecting the life and service of orthopedic appliances made of metals and alloys used as implants in the body, with the release of ions into the body [2]. Problems related to carcinogenicity, allergies, local tissue toxicity, inflammation, genotoxicity are related to metallic ions in tissues surrounding the implants. Another property of a biomaterial when deployed in places prone to wear, such as joints, is to have high wear resistance.

This property improves the stability and proper functioning of the implant device, avoiding the production of wear particles, which lead to an adverse reaction in the tissue in which they are deposited as inflammation, osteolysis, bone resorption and loosening of the implant [3-5]. As an example, commercially pure titanium (Cp Ti) and its alloys are the materials commonly used in orthopedic implants, comprising 70-80% of all materials used [6]. However, despite excellent properties such as excellent biocompatibility, density, toughness and high corrosion resistance, they have high coefficient of wear and friction, that is, they are recognized by poor tribological properties. To solve such problems superficial treatment is one of the methods used to expand the use of metallic implants. Titanium nitride coating (TiN) is used to increase corrosion resistance, surface hardness and to reduce the coefficient of wear and friction of surgical alloys of orthopedic implants [7,8].

Titanium Nitride – Properties

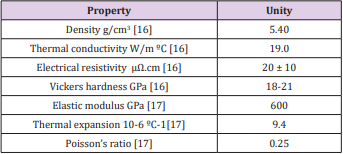

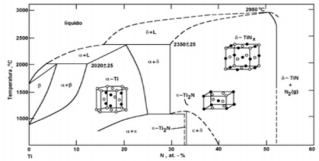

As a ceramic coating, TiN was first introduced in the 1980s in hip and knee prostheses [9]. Titanium nitride is a ceramic material, biocompatible and extremely hard [10], in addition, it has high conductivity and electron mobility as well as a high melting point (2000 - 4000 °C) [11,12], low price [13] and recognized for its high resistance to wear and corrosion [14-17]. Many properties of titanium nitride films have a high dependence on their composition (relationship between the nitrogen/titanium content) and their structure, which is dependent on the growth technique and the deposition parameters employed. However, some TiN coating properties are pointed out, as shown in Table 1. Its most known phases are the δ-TiNx phase that has a cubic face centered structure and the ε-Ti2N phase with tetragonal structure, shown in the phase diagram in Figure 1 [18]. Figure 1 shows that nitrogen addition leads to an expansion of the titanium crystalline lattice to accommodate the nitrogen atoms, with its maximum concentration at 1050 ºC of 23% in atomic weight. For concentrations of nitrogen higher than 23% with temperatures below 1050 ºC, the formation of ε-Ti2N is observed. The δ-TiN phase can be obtained with concentrations of nitrogen of 40 to 55% of atomic weight [19].

The stoichiometry of titanium nitride also influences the visual appearance of the coatings, varying from metallic gray to reddish brown, passing through gold in stoichiometric conditions. The release of metallic ions from the substrate to the organism is reduced with the deposition of the TiN ceramic coating [20,21], as a reduction of bacterial proliferation [21]. The release of metal ions from a ceramic coating is reduced due to improved corrosion resistance [22], besides the coating represents a physical barrier between the substrate and the surrounding environment. With increased wear resistance [15] there is also a reduction in the release of wear particles. Another improved property is the fatigue strength of the biomaterial [10,14,22]. The TiN coating is applied to titanium and its alloys, TiNi alloys, AISI 316L stainless steel, cobaltchromium, nickel-chromium, cobalt-chromium-molybdenum alloys. It is also a coating used in the coating of surgical instruments such as dental tools, files and scissors. One of the main factors for the success of the coating is the good adhesion between the same and the substrate, being determinant in the life time of the component [23]. Poor adhesion may lead to adhesive failure, i.e. delamination of the substrate coating; or a cohesive failure - fracture in the coating [17]. These failures are mainly related to the internal high residual stress of the coatings [17,24]. The most typical approach to increase adhesion is the deposition of a ductile metal interlayer (usually titanium) between the coating and the substrate [17,23]. Research also deals with the production of multilayer TiN coatings with Ti [17,23,25].

More BJSTR Articles: https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.