A Method for Automatic Control of the Process of Dynamic Settling of Oil Emulsion

Introduction

There is a known method for regulating the oil-water interface level using a capacitive sensor with an impact on the flow rate of discharged (drainage) water [1,2] The drawback of this method is that over time, asphalt-resinous substances and high-melting point oil paraffins accumulate on the surface of the sensing element, leading to a change in the gravity of the sensing element and, consequently, to a significant decrease in the accuracy of regulation. We know of a method and a system for automatic control of the oil-water interface level in the process of dynamic settling of oil emulsion [3], where the differential hydrostatic pressure between two specified points located in the upper and lower parts of the settler is measured. However, it has a significant accuracy error due to the expansion of the differential pressure gauge scale.

Problem Statement

Development of a more accurate and reliable method for measuring and regulating the oil and water interface level in settlers of a thermochemical treatment unit, in which dynamic settling of emulsified water droplets in an oil environment is carried out [4].

Solution

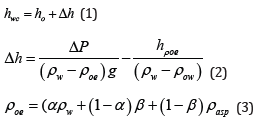

This goal is achieved by first taking samples of the upper pressure gauge and determining in laboratory conditions the density of water and oil, as well as the content of water and asphaltresinous substances in the intermediate emulsion layer (IEL) formed on the surface of the water cushion between the water and oil layers. Then, taking into account the measured values, the water cushion level is determined from the following formula:

where are the water cushion level in the settler, the height of lower pressure gauge and the distance between the gauges, respectively, cm; is the water level (water-IEL interface level) between the gauges, cm; are the density of water, oil and oil emulsion (OE), respectively, kg/cm3; is the differential hydrostatic pressure between the lower and the upper gauges, kg/cm2; are fractional content of water and asphaltenes, respectively.

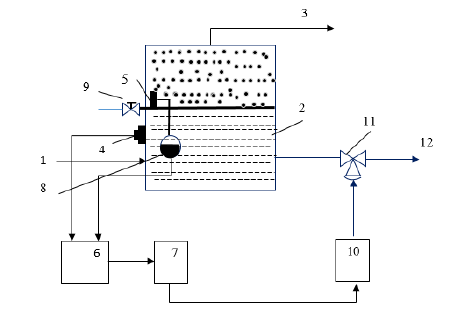

Figure 1 shows a schematic diagram that interprets the operation of the method for automatic control of the process of dynamic settling of OE, which consists in regulating the water cushion level in the TCOTU settler. The method is implemented as follows. Via pipeline 1, OE with increased water concentration enters settler 2. The settled oil with a small (residual) water concentration is removed from the settler via pipeline 3. Pressure gauges 4 and 5 installed at points corresponding to the permissible maximum and minimum water cushion (WC) level, according to the TCOTU master production record, with differential pressure gauge 6 measure the differential hydrostatic pressure (DHP) between points 4 and 5. The output of DHP 6 is connected to the input of control and display unit (CDU) 7. In order to improve the accuracy of DHP measurement, gauge 5 is connected through the separation vessel 8 with the negative chamber of the differential pressure gauge in CDU 7, the values of , determined in laboratory conditions, are introduced. Sampling is carried out at point 9. In the CDU, the WC level is calculated from formulas (1)-(3).

The obtained value from the CIB output goes to WC level regulator 10 connected to actuating mechanism (AM) 11 installed in the drainage water discharge line. In regulator 9, the signal received from unit 7 is compared with the regulator’s setpoint and, if the bias is upward, the flow rate of drainage water increases and vice versa.

Thus, the oil and water interface level (WC) is automatically determined by the differential hydrostatic pressure measured between points 4 and 5, taking into account the quality indicators of OE - .

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.