Making Bee Bread from Pollen Without a Bee Colony

Introduction

The production and use of bee bread by humans is very popular due to the unique properties of the product: it clearly differs from the source material (pollen -pollen load) by its beneficial effect on the living organism. Along with a number of diseases that are positively affected by bee bread, one of the most important aspects is the activity against infectious diseases, which is manifested through strengthening the immune system and accelerating the recovery processes [1,2] (Ахметова и др., 2010). However, bee bread is still produced using traditional methods, which, in turn, is due to seasonality: it is removed from the beehive in spring or late summer; The beekeeper at that time is forced to violate the integrity of the honeycomb with bee bread; Honeycombs are often contaminated with external substances (possible fabrication of artificial honeycomb, bee feed residues, medicinal preparations, etc. Separating bee bread from honeycomb is a rather complex and time-consuming process, which is reflected in the price of the finished product: it may not be available even to ordinary consumers.

Research on Improving the Technological Process

To avoid the above side effects, we took pollen collected by the honeybees as a source material, natural or dried in the oven up to 400C, with a residual moisture of 10-12mass%. In the latter case we restored the initial moisture content in it (26-29%, without violating the integrity of the pollen grains). Together with the water, a specialized strain of lactic acid microbe was added, with the ability to act in conditions of high concentration of the substrate from pre-selected different species. As a nutrient medium for the microbe, completely hydrolyzed sucrose (invert sugar) was used, from which lactic acid was obtained as a result of fermentation. The limits of active acidity (pH) in the finished product should be 4.1- 3.9. The incubation process was positively affected by the formation of CO2 in the material to be processed, which took no more than 50 hours. In order to prevent the development of any undesirable microbial processes in the finished bee bread, it was partially dried with a moisture content of 16-17mass%. In addition, honey of similar moisture with high antimicrobial activity was added to the bee bread in limited quantities. According to Чудаков [3], chestnut honey is distinguished by such properties that somewhat reduce the astringency in bee bread, but do not suppress the specific taste properties. Drying was carried out at atmospheric pressure, at a temperature of 38-400C according to the technology developed by us (Copyright # 5870) [4], at a humidity of 16-17%, and its duration did not exceed 4.5-5 hours. To protect it from atmospheric oxygen, a carbon dioxide field was created in the glass jars, ensuring perfect color and appearance preservation during the long-term storage process.

Safety Check of the Received Product

The Developed Technology is Somewhat Different from the Process of Making Bee Bread in a Beehive, Namely:

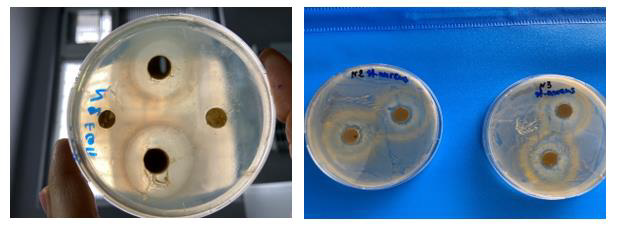

In the latter case, bee bread is made from raw pollen at a temperature of 33-350C for 15-17 days. According to our technology, bee bread is made mainly on the basis of dried pollen, with its initial moisture recovery up to 26.4-28.8%, with the addition of specialized lactic acid microbes and invert syrup. The total duration of the process is 50-60 hours, depending on the activity of the microbial culture. In both cases, due to the anaerobic conditions created and the high content of protein, undesirable microflora may develop in the product. Such cases are mentioned in the process of making natural bee bread (Ms. N. Chakvetadze, personal message). Because of these considerations, it was considered appropriate to determine the possible reproduction of various species of microorganisms in the finished product, including transportation, reproduction of botulism-causing spores in vegetative form and the possibility of accumulation of toxins. The work was carried out at the National Center for Disease Control and Public Health (m-r R. Lugar’s laboratory). At the initial stage of the work, the safety of the bee bread samples prepared by us as a food supplement was tested in white mice administered orally. It was found that the product had no negative effect on the experimental animals. At the next stage, the components of the finished product were infected with botulism spores, the samples were placed in the incubator for 10 days at 370C and then given to the experimental group white mice. The control group received the usual portions. During the experiment, no cases of poisoning or killing of experimental animals were reported. So, there is no possibility of reproduction of botulism-inducing spores in the bee bread made according to the developed technology. Another experiment was conducted at the Biorational Technologies Research Center of Georgia to determine the effectiveness of the action of Esherichia coli and Staphylococcus aureus microbes in the nutrient medium by adding both pure bee bread and honey added product. Meat-peptone agar was used as a nutrient medium. The incubation period mode included the reproduction of these microbes over a 24-hour period. The results of these observations are presented in the form of photos below (Figure 1). When pure bee bread and mixture of bee bread and honey are exposed to both microbes, their growth inhibition zones are clearly defined: for Esherichia coli -33 mm and for Staphylococcus aureus -31 mm, which confirms the preservation of antimicrobial activity of this product in the processing of pollen [5].

Figure 1: The zones of growth inhibition of Esherichia coli and Staphylococcus aureus by bee bread preparations.

Results of Biochemical Studies of Bee Bread

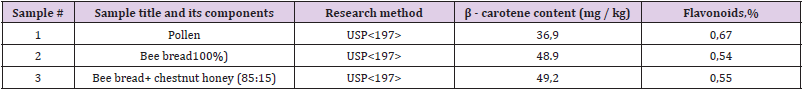

The researchers conducted a biochemical characterization of the resulting product: oxidation rate, hydrogen ion concentration. The content of β-carotene and flavonoids was determined in the examination laboratory of “Global-Test” LLC. The results are given below. Oxidation was determined in accordance with GOST 31 776-2012, which limits it to 23 seconds (not more) and is based on the bleaching of 0, 1 mol / cm3 permanganic acid potassium. The oxidation time for bee bread samples made in different periods ranged from 12 to 18 seconds, which met the requirements of GOST. As for hydrogen ion concentration, according to the same GOST, the indicator should be at least 3, although, according to the norms of animal feed (silage), the most acceptable was 3.8-4.2. If the pH was less than 3.6, it meant that the food was too acidic and needed to be acidified. Such a low rate (high acidity) of bee bread should probably be due to the excess honey content in the starting material. Regarding this indicator (4,1-3,8), we recommended that the bee bread be preserved and normalized by optimizing the addition of monosaccharides and lactic acid bacteria (Table 1).

According to the analysts, the lower content of β-carotene in the initial product (pollen) is due to the insufficient ability to extract the solvent used (Karez I and II). As for the bee bread samples, the amount of β-carotene and flavonoids in them is almost equal. A noticeably higher number of flavonoids in the source product requires to be specified for a wider range of materials. According to the preliminary results of the biochemical study, no deterioration of the indicators was observed during the processing of the bee bread material. According to the results of microbiological research, the product retains its biological activity, evidenced by the morphological indicators of pollen and bee bread (see photos) (Figure 2). Depending on the color of the samples, it can be assumed that it does not change much during the processing. Its change is observed only if the components of bee bread (honey and bee bread) have dramatically different colors, although this does not indicate a deterioration in the quality of the product already obtained.

The Main Technological Equipment Required for the Production of Bee Bread Includes

Biological thermostat, drying oven with enhanced internal aeration, vacuum chamber, pressure cylinder with reducer. The non-standard device is equipped with a mixer of bee bread and honey, maintaining the grain structure of the bee bread, which is one of the elements of providing the purity of the product. Due to the lack of such a machine, the work is still done manually, although this operation does not have a significant impact on the cost of the product [6].

Technical and Economic Evaluation of Bee Bread Production

The following technological innovations are included in the production of this product:

1. Overall simplification of the process: Instead of removing from the honeycomb, well-developed technology for collecting pollen in beekeeping with subsequent processing in a laboratory or enterprise.

a) Biotechnological method of processing pollen with a total duration of 55-60 hours, instead of 2.5 weeks (traditional method).

b) Simplicity and cheapness of the technological device.

2. The economic effect of a product is determined by several parameters:

a) To determine the cost price, we can use the scheme: the market price of raw materials + 30% of its amount in the form of production costs.

b) Market price includes % of profit, which can be defined as: cost + profit. If the market price of the dried pollen amounts to 45-50 GEL, then the final cost of the bee bread is likely to be 120-130 GEL.

c) The price of the bee bread obtained in a traditional way is now 300 GEL. Consequently, the new technology enables us to reduce the cost of the finished product by about 2.3 times.

Conclusion

1) The biotechnological method developed for the conversion of pollen into a bee bread allows the work to be carried out in the same way as the process in the beehive-lactic acid fermentation. These works can be performed within 55-60 hours while maintaining product quality and health benefits.

2) The novelties used in the production process of bee bread are as follows: Lactic acid production at the expense of fully inverted sucrose; Replacement of atmospheric air with carbon dioxide during both fermentation and storage; Drastic reduction in the time required to produce the product (55-60 hours instead of 2.5 weeks); Optimization of the humidity of the finished bee bread for 4.5-5 hours at a temperature of no more than 400C, with enhanced internal aeration of the drying oven; Enhancing the antimicrobial properties of bee bread using a limited amount of highly active honey;

3) The developed technology makes it possible to inhibit harmful microorganisms in bee bread: Clostridium botulinum, Esherichia coli and Staphilococcus aureus even in conditions of deliberate infection of the product, while its qualitative indicators (pH, oxidation, β-carotene and flavonoids content) remain at the level of standard requirements.

4) Innovative production of bee bread (without bee colony) can radically reduce its market price (2.3 times), implement the process at any time of the year, increase the consumption of bee bread by the less affluent people and include it in export products, which are based on its incomparably low price-basic demand for competitive products.

For more Articles on: https://biomedres01.blogspot.com/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.