The Effect of the Initial Moisture Content of the Wheat- Triticale Grain Mixture in the Ratio of 50/50% on the Yield of Whole Wheat-Triticale Groats

Introduction

The nutritional and nutritional value in wheat grains and triticale is represented by the starchy endosperm. It is surrounded by cells of the aleurone layer of irregular shape and varying thickness, consisting mainly of cellulose. Next to the periphery are the seed and wrinkled scaly fruit membranes. To obtain wheattriticale groats, all the outer layers surrounding the endosperm must be removed. In addition, in wheat and triticale, the seed coat enters deeply into the grain cavity in the form of a groove [1-6]. One type of cereal is considered in the form of a whole from a wheat-triticale grain mixture. The technology of producing whole cereals provides for the removal of coarse seed membranes from the endosperm with minimal crushing of the nucleus at the same time, which inevitably and necessarily happens. The surface of the whole cereal should be monophonic, light, smooth. In the mass, the whole cereal should be aligned in size, in color and in the degree of processing. The shells and aleurone layer surrounding the endosperm are usually removed by peeling the grain and finer grinding.

Crushed cereals are produced by grinding the whole kernel, followed by sorting by size. The surface of crushed cereals should be freed from external, coarse shells and uniform in color, according to the state of the surface, the mass of crushed cereals should be aligned in size [7]. Domestic scientists have developed a technology for obtaining cereals from triticale grain. It was established that humidity and coarseness directly affect the yield of finished products, and the technological moisture content of grain equal to 15% was also determined, which made it possible to achieve the yield of triticale cereals up to 55% [3]. Obtaining low-calorie and nutrient-rich cereals from sprouted grains of wheat, rye, and barley is advisable and possible. The chemical properties of this cereal allow this product to be absorbed faster and more efficiently [8-13]. Analyzing the literature data, it is important to note that the issue of production of cereals from the wheat-triticale grain mixture, the lack of a well-developed technology for its production, as well as regulatory and technical documentation and methods for assessing the quality of finished products have not been studied. The purpose of our research is to determine the effect of the initial moisture content of the wheat-triticale grain mixture in the ratio of 50/50% on the yield of whole wheat-triticale cereals.

Method

In studies conducted at the Department of Grains, Bakery and Confectionery Technologies of the Federal State Budgetary Educational Institution of Higher Education “MGUPP”, the effect of the initial humidity of the wheat-triticale grain mixture in the ratio of 50/50% on the output of whole wheat-triticale cereals was investigated. Peeling of various samples of wheat-triticale grain mixture in a ratio of 50/50% was carried out on a laboratory peeler of the company “Satake” (Japan). Abrasive peeling for each sample of wheat-triticale grain mixture was carried out in 3 steps for 240 seconds (90, 90 and 60 seconds, respectively) and in 5 repetitions with the determination of the average value.

Outcomes

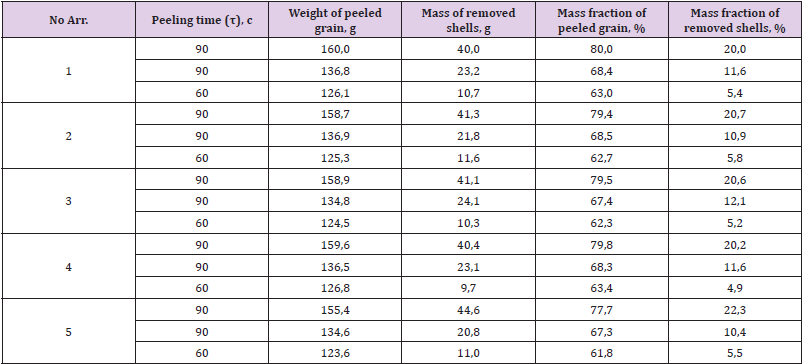

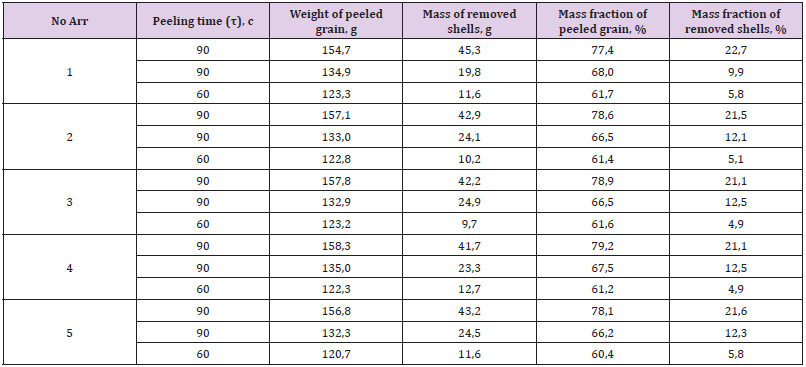

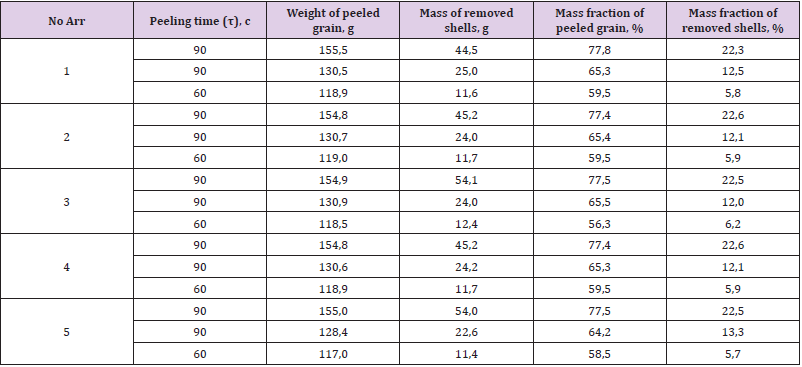

Table 1 presents the results of experimental data on the yield of whole wheat-triticale groats from a wheat-triticale grain mixture with an initial humidity of 11.0%. As can be seen from Table 1, as a result of 3-stage abrasive peeling, the total yield of whole wheattriticale cereals from the original wheat-triticale grain mixture with an initial humidity of 11.0% was 62.6%. At the same time, at the first stage of abrasive peeling of the wheat-triticale grain mixture, 20.8% of the shells were removed within 90 seconds, at the second stage of abrasive peeling, 11.3% of the shells, aleurone layer and endosperm were removed within 90 seconds and at the third stage of abrasive peeling, 5.4% of the endosperm was removed within 60 seconds. Table 2 presents the results of experimental data on the yield of whole wheat-triticale cereals from a wheat-triticale grain mixture with an initial humidity of 11.7%. As can be seen from Table 2, as a result of 3-stage abrasive peeling, the total yield of whole wheat-triticale cereals from the initial wheat-triticale grain mixture with an initial humidity of 11.7% was 61.2%. At the same time, at the first stage of abrasive peeling of the wheattriticale grain mixture, 21.6% of the shells were removed within 90 seconds, at the second stage of abrasive peeling, 11.9% of the shells, aleurone layer and endosperm were removed within 90 seconds and at the third stage of abrasive peeling, 5.4% of the endosperm was removed within 60 seconds. Table 3 presents the results of experimental data on the yield of whole wheat-triticale groats from a wheat-triticale grain mixture with an initial humidity of 12.5%.

Table 1: Yield of wheat-triticale whole cereals from wheat-triticale grain mixture with a starting humidity of 11.0%.

Table 2: Yield of wheat-triticale whole cereals from wheat-triticale grain mixture with a starting humidity of 11.7%.

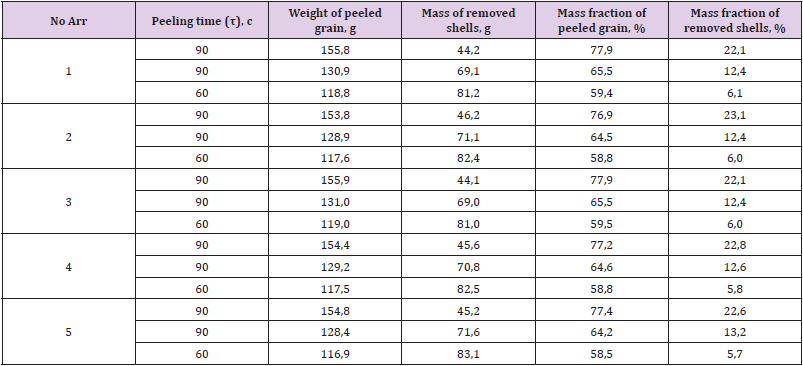

As can be seen from Table 3, as a result of 3-stage abrasive peeling, the total yield of whole wheat-triticale cereals from the initial wheat-triticale grain mixture with an initial humidity of 12.5% was 59.0%. At the same time, at the first stage of abrasive peeling of the wheat-triticale grain mixture, 22.5% of the shells were removed within 90 seconds, at the second stage of abrasive peeling, 12.6% of the shells, aleurone layer and endosperm were removed within 90 seconds and at the third stage of abrasive peeling, 5.9% of the endosperm was removed within 60 seconds. Table 4 presents the results of experimental data on the yield of whole wheat-triticale groats from a wheat-triticale grain mixture with an initial humidity of 13.4%.

Table 3: Electric output of wheat-triticale whole groats from wheat-triticale grain mixture with a starting humidity of 12.5%.

Table 4: Yield of wheat-triticale whole cereals from wheat-triticale grain mixture with a starting humidity of 13.4%.

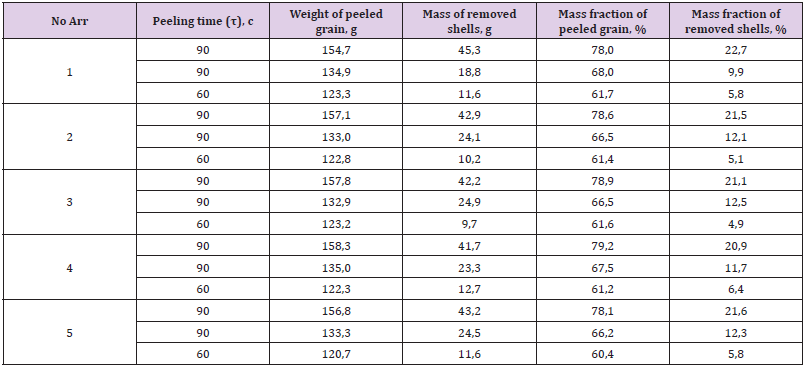

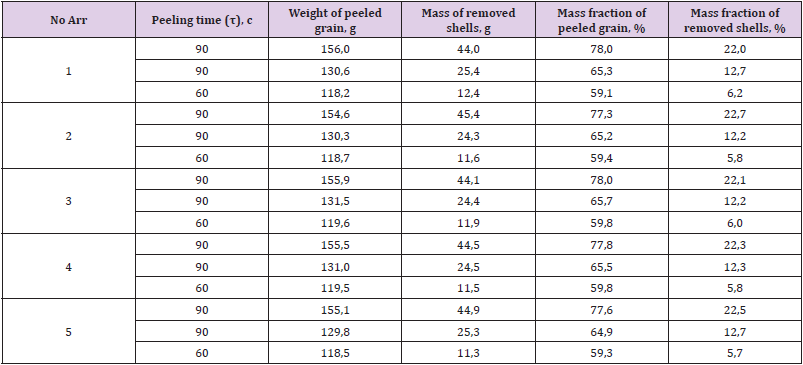

As can be seen from Table 4, as a result of 3-stage abrasive peeling, the total yield of whole wheat-triticale cereals from the initial wheat-triticale grain mixture with an initial humidity of 13.4% was 61.2%. At the same time, at the first stage of abrasive peeling of the wheat-triticale grain mixture, 21.5% of the shells were removed within 90 seconds, at the second stage of abrasive peeling, 11.7% of the shells, aleurone layer and endosperm were removed within 90 seconds and at the third stage of abrasive peeling, 5.4% of the endosperm was removed within 60 seconds. Table 5 presents the results of experimental data on the yield of whole wheat-triticale groats from a wheat-triticale grain mixture with an initial humidity of 14.3%.

Table 5: Yield of wheat-triticale whole cereals from wheat-triticale grain mixture with a starting humidity of 14.3 %.

As can be seen from Table 5, as a result of 3-stage abrasive peeling, the total yield of whole wheat-triticale cereals from the original wheat-triticale grain mixture with an initial humidity of 14.3% was 59.2%. At the same time, at the first stage of abrasive peeling of the wheat-triticale grain mixture, 22.5% of the shells were removed within 90 seconds, at the second stage of abrasive peeling, 12.4% of the shells, aleurone layer and endosperm were removed within 90 seconds and at the third stage of abrasive peeling, 5.9% of the endosperm was removed within 60 seconds. Table 6 presents the results of experimental data on the yield of whole wheat-triticale groats from a wheat-triticale grain mixture with an initial humidity of 15.6%. As can be seen from Table 6, as a result of 3-stage abrasive peeling, the total yield of whole wheattriticale groats from the initial wheat-triticale grain mixture with a reference humidity of 15.6% was 59.5%. At the same time, at the first stage of abrasive peeling of the wheat-triticale grain mixture, 22.3% of the shells were removed within 90 seconds, at the second stage of abrasive peeling, 12.4% of the shells, aleurone layer and endosperm were removed within 90 seconds and at the third stage of abrasive peeling, 5.9% of the endosperm was removed within 60 seconds. Figures 1 & 2 show photographs of the original wheat-triticale grain mixture and the whole wheat-triticale groats obtained as a result of 3-stage abrasive peeling.

Table 6: Yield of wheat-triticale whole cereals from wheat-triticale grain mixture with a starting humidity of 15.6 %.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.